Advantages of Two-component Epoxy Resin Adhesive

Extreme strength and resistance to thermal and mechanical influences

Resistant to most aggressive substances and oils

Available solvent free and BPA free

It hardens even under water

Compatible with a wide range of additives such as dyes and accelerators

Expedited Potlife

Application – BestPractice

At room temperature (15-30 C

The mixing ratio of the two components of 1: 1 is maintained automatically. Do not apply below 5 C outdoor temperature. The higher the ambient temperature, the more effectively the material polymerizes. This means that resistance increases at higher temperatures.

It is recommended to have a cloth ready for cleaning. In addition, care must be taken that the work surface is protected and can be cleaned directly if necessary.

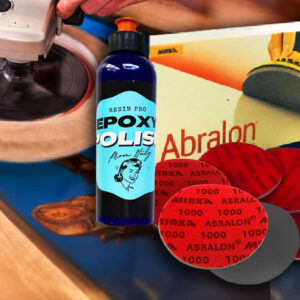

The surface should be slightly roughened, because only then is the epoxy adhesive guaranteed to bond well with the material. To do this, you can sand or file the surface.

To spread the sticker, a piece of cardboard or plastic is useful. After use, clean the tube so that the lid does not stick, and then close it tightly. The thickness of the adhesive should be thin enough (0.1-0.2 mm), but if necessary it can be thicker.

The parts to be glued must be clean and free of oil and grease. Apply the adhesive on one side and join and press the parts to be glued. The potlife is about 5 minutes, good endurance is achieved after about 10-12 minutes, and total endurance after about 24 hours.

Pot life is limited in time and describes the maximum working time of the uncured adhesive. Once the pot life has passed, the adhesive not yet applied must not be further processed, but must be disposed of!

Until the manual force is reached, the binding must be additionally fixed, for example, with the help of a vice, adhesive tape or clamp.

In the case of heat-assisted polymerisation, the temperature resistance of the joined parts must be guaranteed. In addition, the heating and cooling times of the parts to be joined must be respected. This time must be added to the curing time of the adhesive. Tension can occur in the glued joint during heating and cooling.

With materials such as PP, PE, PTFE or silicone, the parts need to be pretreated with our primer.

The need for a primer depends on the surface tension. If this is high enough it can be tested with water droplets on the surface. If the drops adhere well to the surface, a good bond is most likely. If the drops slip away, a primer is probably needed.

Mixing

There are several ways to mix the two components:

– Mixing by hand

– Use of a static mixing nozzle

– Use of a dynamic mixing nozzle

Hand mixing is sufficient in most cases. For this purpose, a toothpick or similar is used and the two components are mixed until a cloudy mass is formed. Make sure that no bubbles remain.

When using a static mixing nozzle, the mixing of both components takes place inside the mixing nozzle so that the mixing is ideal. The first 2g should be discarded, given they are not yet mixed 1:1. However, the mixing nozzle can only be used until the adhesive in the mixing nozzle has dried. After that, you will need a new nozzle.

W

With a dynamic mixing nozzle, the speed of the mixer can be controlled electronically. This allows you to control the mixing intensity very precisely. However, this is intended for special industrial applications and is not necessary for everyday use.

Harden

The adhesive is chemically cured. This gives the advantage that gluing the surface is also possible, where adhesives that harden with moisture take a very long time.

The bond is high strength and densely flexible. Thus, permanent resistance can be guaranteed in the event of shocks and vibrations. The use of the polymerised adhesive is also possible at high temperatures (up to about 120C), for a short time (30 min) up to 200C

The polymerised adhesive has good resistance to physical (e.g. sunlight) or chemical (moisture, detergents, chemicals, etc.) influences.

The great advantage of two-component epoxy adhesive is the fact that it hardens even under water and is robust. In addition, it is mouldable, so it can be inserted into any recess to fit.

Technical data

Epoxy Resin Hardener Base (amine mixture)

Viscosity High Viscosity

Transparent Color

Density 1.1 g / ml

Gap filling capacity 3mm

Temperature resistance -40 up to +120 C

Pot Life 5 min

Hand resistance 10-12 min

Final endurance 24 hours

Shore hardness 60

Tensile shear strength 10 N / mm2

Module E 620 N / mm2