On sale

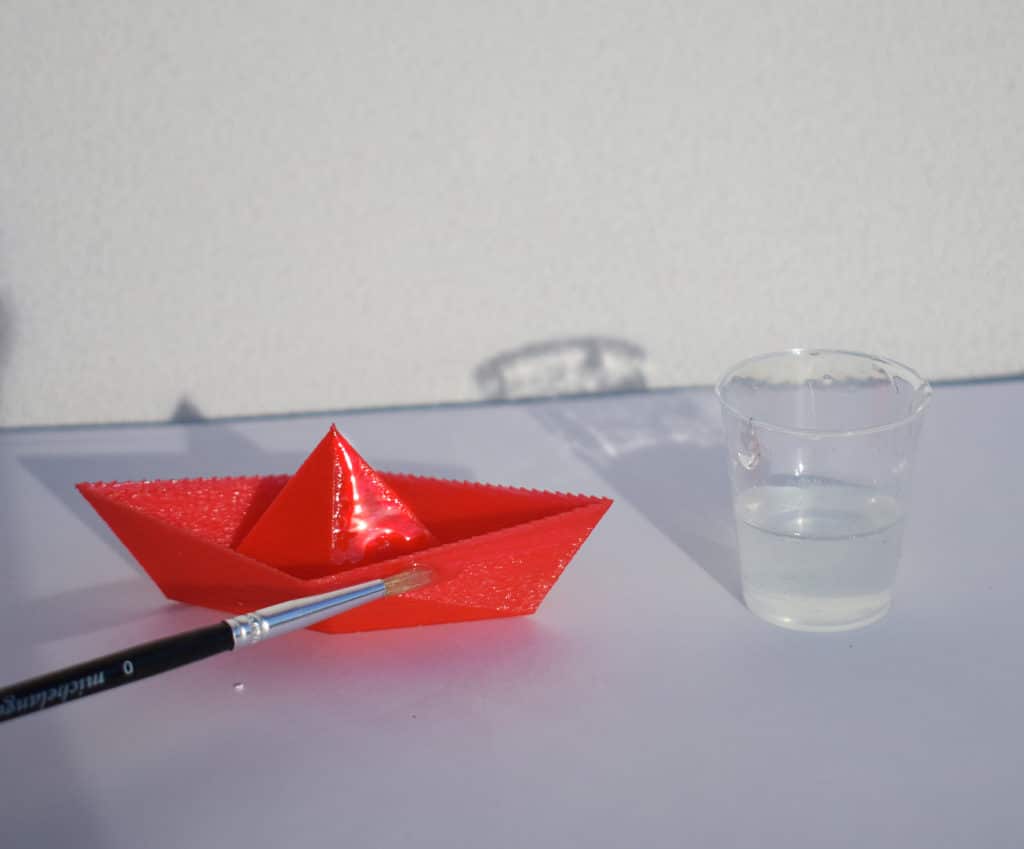

“3D Finish” – Fast Coating Resin for 3D Prints

Price range: £12.85 through £18.85

Fri, 13. Feb

Ordered

Fri, 13. Feb - Mon, 16. Feb

Order Shipped

Mon, 16. Feb - Tue, 17. Feb

Estimated delivery

3D Finish Fast Coating Epoxy Resin for 3D Prints delivers a seamless, glossy, non-drip post-print coating that enhances mechanical strength and visual quality in PLA, ABS, and LAYWOOD models. Perfect for hobbyists and professionals, it preserves fine details while eliminating layer lines and is ideal for coating, bonding, and repairing 3D printed parts.

- ✨ Accelerated 4-hour curing at 20°C

- 🔗 Exceptional adhesion for popular 3D printing materials

- 🌟 Detail-preserving formula that eliminates layer lines

- 🛠️ Polishable and paintable surface

- 🔧 Versatile use for bonding and repairing 3D prints

Description

💥 About

3D Finish Fast Coating Epoxy Resin is expertly designed for finishing and protecting 3D prints. Perfect for makers and DIY enthusiasts, this high-quality, non-drip post-print coating (does not flood fine details) delivers a strong, smooth, and polished surface for any PLA, ABS, or LAYWOOD model. Its fast-curing formula transforms prints by eliminating rough layer lines without sacrificing detail, enhancing both visual appeal and durability.

💡 Key Benefits

- Rapid 4-hour curing – Set projects aside and enjoy a full cure in just 4 hours at 20°C. ⏱️

- Outstanding adhesion – Bonds seamlessly to PLA, ABS, LAYWOOD, and more, ideal for bonding and repairing 3D printed parts. 🔗

- Detail-preserving formula – Smooths prints while retaining sharp geometry and fine features. 🌟

- Mechanical reinforcement – Boosts impact resistance and fills layer inconsistencies. 🔨

- Custom finish options – Polish or paint with colouring additives and metal powders. 🎨

☝🏽 Useful Information

- Volume: Multiple sizes available for small batches or large projects

- Application: Simple brush or spread-on process for a professional result

- Material Compatibility: Optimised for the most common 3D print plastics

🎯 Who It’s For

- – Hobbyists and DIY enthusiasts

- – Professional makers

Upgrade your 3D printing workflow with a fast, professional finish. Trusted by creators to deliver flawless, resilient surfaces for every project.

Technical data

TECHNICAL DATA

“3D-FINISH” – Fast Coating Resin For 3D Prints

- Mix ratio: 100A : 50B (by Volume); 100A: 45B (Mix ratio based on weight)

- Viscosity: Resin – 800 mPas; Hardener – 300; Mix – 450

- Cure time: 4 hours at 20°C [68 F]; 2 hours at 30°C [86 F]

- Hardness: Shore D 80 EN ISO 868

- Working time: (125 g 25°) 20 min

- Coverage 1kg: 100*60*0.15cm

- 1sqm consumption (1.5mm thickness): 5kg

Instruction

For best results, measure two components based on weight using a scale within 5% of the recommended mix ratio –

100A : 50B (by Volume); 100A: 45B (Mix ratio based on weight)

- Always mix the product thoroughly for at least 2 minutes, scraping all the surfaces of the container to ensure complete mixing.

- Try to use the product in a temperature-controlled environment within the optimal product specifications.

- Avoid high humidity or low ambient temperatures.

- Ensure that the surface is dry and any dirt, dust and oils removed to achieve optimal bonding. It is furthermore highly recommended to sand the surface (with sandpaper or mechanical preparation).

- Perform small preliminary tests to have a clear understanding of the polymerization features of the resins in your work environment and the compatibility of the resins with other materials.

WARNINGS:

During processing, use protective masks, gloves, and other protective clothing.

In case of contact with eyes, immediately rinse with cold water for 15 minutes and immediately consult a doctor.

Reviews

💥 About

3D Finish Fast Coating Epoxy Resin is expertly designed for finishing and protecting 3D prints. Perfect for makers and DIY enthusiasts, this high-quality, non-drip post-print coating (does not flood fine details) delivers a strong, smooth, and polished surface for any PLA, ABS, or LAYWOOD model. Its fast-curing formula transforms prints by eliminating rough layer lines without sacrificing detail, enhancing both visual appeal and durability.

💡 Key Benefits

- Rapid 4-hour curing – Set projects aside and enjoy a full cure in just 4 hours at 20°C. ⏱️

- Outstanding adhesion – Bonds seamlessly to PLA, ABS, LAYWOOD, and more, ideal for bonding and repairing 3D printed parts. 🔗

- Detail-preserving formula – Smooths prints while retaining sharp geometry and fine features. 🌟

- Mechanical reinforcement – Boosts impact resistance and fills layer inconsistencies. 🔨

- Custom finish options – Polish or paint with colouring additives and metal powders. 🎨

☝🏽 Useful Information

- Volume: Multiple sizes available for small batches or large projects

- Application: Simple brush or spread-on process for a professional result

- Material Compatibility: Optimised for the most common 3D print plastics

🎯 Who It’s For

- – Hobbyists and DIY enthusiasts

- – Professional makers

Upgrade your 3D printing workflow with a fast, professional finish. Trusted by creators to deliver flawless, resilient surfaces for every project.

TECHNICAL DATA

“3D-FINISH” – Fast Coating Resin For 3D Prints

- Mix ratio: 100A : 50B (by Volume); 100A: 45B (Mix ratio based on weight)

- Viscosity: Resin – 800 mPas; Hardener – 300; Mix – 450

- Cure time: 4 hours at 20°C [68 F]; 2 hours at 30°C [86 F]

- Hardness: Shore D 80 EN ISO 868

- Working time: (125 g 25°) 20 min

- Coverage 1kg: 100*60*0.15cm

- 1sqm consumption (1.5mm thickness): 5kg

For best results, measure two components based on weight using a scale within 5% of the recommended mix ratio –

100A : 50B (by Volume); 100A: 45B (Mix ratio based on weight)

- Always mix the product thoroughly for at least 2 minutes, scraping all the surfaces of the container to ensure complete mixing.

- Try to use the product in a temperature-controlled environment within the optimal product specifications.

- Avoid high humidity or low ambient temperatures.

- Ensure that the surface is dry and any dirt, dust and oils removed to achieve optimal bonding. It is furthermore highly recommended to sand the surface (with sandpaper or mechanical preparation).

- Perform small preliminary tests to have a clear understanding of the polymerization features of the resins in your work environment and the compatibility of the resins with other materials.

WARNINGS:

During processing, use protective masks, gloves, and other protective clothing.

In case of contact with eyes, immediately rinse with cold water for 15 minutes and immediately consult a doctor.

COD:

5P-2ELA-VK07

Google

Google