TECHNICAL DATA

“EPOXYTABLE 10-TEN” – epoxy resin for large projects – casting up to 10cm

-Mix ratio: 4:1 by weight

-Coverage: 1kg of mix epoxy+hardener covers area 30*30*1cm.

-Pot-life: (125 gr at 25°C) [0,27lb at 77F]:24h

-Full catalysis: 5-7 days

-Demoulding time: 3-5 days

-Gel time: (125 gr at 25°C) [0,27lb at 77F]: 48-72h

-Maximum pouring level: 10cm*

-Minimum pouring level: 5mm

–Heat resistance:up to 70°C

-Viscosity: Resin – 1900 mPas; Hardener – 40 mPas; Mix – 400 mPas

* – may vary from the pouring`s conditions, please, read the instruction.

If you have not enough experience, we highly recommend to make a small test before working with large project.

Main features:

High transparency / Strong UV-resistance / Super Deep pour resin / Long working time.

Applications:

DIY / Coating up to 10cm / Wood working / Modelling / Artistic creations / Adhesive.

💪🏽 LET`S START! 💪🏽

We would like to pay your attention – We don`t recommend working at temperatures below of 20 ° C and over 28 ° C, avoiding humid environments (or surfaces) application (if you are not sure on the humidity, let the resin warm up the components before pouring).

If epoxy resin was storage at temperatures below of 20 ° C and became murky, please, warm your epoxy up before using to full transparency. More detailed, please, read below.

👉🏽 LET`S MIX! 👈🏽

THE PROPORTIONS ARE PRINTED ON THE BOTTLES/TANKS, PLEASE CHECK IT BEFORE USING.

Being a two-component resin, you have 2 bottles at your disposal, one containing resin “A” and the other containing hardener “B”. You will need some electronic scales to weigh grams and a mixing container where you can combine the liquids.

How to calculate, how much hardener do you need? Take your proportions –JUST AN EXAMPLE – 100:25. Then take the weight of component A and multiply on B, (if 100:25 – A*0.25; if 100:70 – A*0.70; if 100:87 – A*0.87).

Please, use some electronic scales and weigh in grams to get the best results.

After an accurate dosage, the resin must be mixed irregularly (meaning, always in the same direction) for at least 5-8 minutes. This part is very important, because if it is mixed only for a few seconds, it will not be homogeneous at the molecular level, therefore will remain soft / opaque in some parts.

Mix evenly on the edges and bottom of the container. (Do not mix very quickly or forcefully because that would cause a lot of bubbles). We do not recommend using a mixer (of course, you can, but, please, not at high speeds!), as this leads to the formation of microbubbles, which will be difficult to remove. The carefully you mix – the less bubbles.

Remember, the quality of the future casting depends on a good mixing of the two components!

Important! Try to make the mix carefully, so that the smallest fractions of air are not formed in the resin, because visible bubbles will easily disappear from the surface naturally, and micro fractions of air are often practically invisible, but during the curing and heating of the epoxy mixture, the air in them expands and after complete curing, bubbles can be visible in the casting. This can and should be avoided if you do the kneading correctly.

How to remove the bubbles?

Although degassing (vacuum) is necessary to eliminate 100% of the bubbles, there are some tricks that can help you minimize the presence of bubbles during the creations.

1) Mix the resin longer but in a more delicate and uniform way.

2) Before mixing, heat component A (in the sun or using a radiator), so that it becomes more liquid and the bubbles rise more easily.

3) Leave it to rest for a few minutes to release the air bubbles.

4) Once launched, use a heat source (thermal pistol or fire, NOT a hairdryer) to burst the bubbles on the surface.

👋🏼 LET`S COLOUR! 👋🏼

Practically everything, including powder and metallic pigments. As long as the dyes are “dry” (for example, dust or sands) there are no problems (as long as they are perfectly dry), when, instead, you want to add pastel or liquid colours, make sure they are compatible with epoxy resins. If they are not compatible (for example enamels, tempera, acrylics) only a few drops can be added, since an excessive dosage could compromise the mechanics of the resin and its brightness (for example making it soft or sticky). There is also a “gold rule” – no more than 5% from mix weight.

Remember, it`s important to avoid contact of epoxy resin with water! From the ingress of water into the resin, it may become cloudy or not solidify! And if the hardener has been stored for a long time with a loosely twisted lid, then it can absorb moisture and it condenses in the form of microbubbles in the thickness of the casting during the curing process.

👍🏽 WHAT`S NEXT? 👍🏽

After pouring epoxy into your formwork be ensured in the “sterility” of the room so that dust and dirt will not get into the epoxy.

Important! We don`t recommend covering the filling with plywood or something dense, because this will disrupt the heat sink during the solidification of the resin!)

Remove micro-bubbles stuck in the surface layer using a hair dryer or a manual gas burner. We also recommend that you do not overheat the epoxy filling with a burner or a hair dryer, because this can cause overheating and boiling of the resin.

The full curing time of the EPOXYTABLE resin is from 7 days (depending on the temperature and humidity in the workshop. The lower the temperature and the higher the humidity, the longer the curing time of the resin.

❄️ FROZEN EPOXY ❄️

Epoxy can become frozen under 20C. PLEASE! DON`T USE FROZEN EPOXY. This may affect the result.

There is no excuse that you hold your epoxy inside a warm room, the epoxy could be frozen much before, and only proper defrosting will return the lost transparency and liquidity.

How to understand why your epoxy was frozen? The component A is murky or solid, like frozen water. Don`t worry, there is no need to dispose of your epoxy and run to leave a bad review. It`s okay. You need to do only one thing – to defrost it, warming component A to 50-70 ° C. We usually put the closed tank inside the sink with very hot water and leave it for 20-30 minutes. The problem is next – the more epoxy inside the tank, the more difficult to warm it properly, so just repeat the procedure. If it doesn`t help, just try again, because we sold thousands of tons of the epoxy resin and every time the problem was sorted out by waiting a little bit longer in hot water (of course with the closed lid). Yes, we totally understand that it causes excessive movements, but it`s natural and it could happen with any other epoxy.

Of course, after defrosting you need to cool the component A to room temperature before using.

🔥 HOW TO AVOID OVERHEATING? 🔥

Maximum pouring level: 10 cm. It may vary from the full weight of poured epoxy, sizes of project and temperature when you pour. Not following instructions may cause overheating.

If you need to make a larger layer, just pour in several steps, waiting 8-10h the first time; 10-12h in the second time and 12+h the third time).

When creating a coating with epoxy resin, do not fill the mixture with a thickness of less than 1.5-2 mm, otherwise, after curing, there is a chance of shrinkage with the formation of “craters” – small depressions on all surfaces of the fill.

If one side of casting is more than 100cm long, please, create your project in layers (each layer being 1-2cm thinner than recommended) with a time interval like above – (waiting 8-10h the first time; 10-12h the second time and 12+h in the third time).

If you do a Round casting, and the required weight A+B exceeds 3kg, create your project in the same way as above (less thickness per application + longer waiting between layers).

Be especially careful when working with resins for large castings, when mixing a large amount of resin, do not leave the mixture for a long time in one container – pour it immediately into other smaller containers to avoid the “mass” effect: the resin begins to heat up quickly and hardens instantly with defects without the chances to change it in any way.

IF YOU MEET MORE THAN ONE EXCEPTION IN YOUR PROJECT, REDUCE THE SIZE OF YOUR APPLICATION AGAIN.

🌊 HOW DO I ELIMINATE SURFACE OPACITIES OR SMALL WAVES FORMED AS THEY SOLIDIFY? 🌊

These surface opacities are the result of the interaction with environmental humidity, which creates a patina on the surface of the cast. At first it is not obvious, but as soon as it starts to solidify, in some places you can notice opaque halos and even “wrinkles”.

There are different strategies to avoid this:

1. Work in low humidity (dehumidified) conditions or in a heated environment.

2. Heat the 2 components before mixing (for example, holding them over a radiator).

3. Mix the resin with the hardener and apply it only when it starts to heat up (so that the reaction begins while it is still in the container). This operation is essential, but requires minimal attention. It should be checked every 5-6 minutes and as soon as it reaches 40 ° C (when it’s warmer than our hand) it can be applied. Otherwise, it could start solidifying in the container!

4. It is advisable not to apply during the night or when it is raining (since the humidity increases).

5. Do not apply on surfaces that still contain humidity, like on fresh cement or on non-dried wood.

– If due to humidity, the resin is not glossy, no problem: just pour a new layer over (following the instructions above) and it will become perfectly transparent and regular.

Additional tips:

1) For easier removing from the formwork, we recommend to cover the formwork by our special film “shiny shield“, before pouring.

2) We do not recommend using a mixer (especially at high speeds), as this leads to the formation of microbubbles, which will be difficult to remove. The carefully you mix – the less bubbles.

3) If you`re going to embed something in your project while curing, do not leave it overnight, because it always becomes solid much faster than you could expect (curing times vary depending on temperature, mixing time, volume and etc). We always advise pouring in the morning then swirling through the day.

WARNINGS:

During processing, use protective masks, gloves, and other protective clothing.

In case of contact with eyes, immediately rinse with cold water for 15 minutes and immediately consult a doctor.

FAQs

“EPOXYTABLE 10-TEN” – epoxy resin for large projects – casting up to 10cm:

Q. What`s the proportions and how to calculate that?

A. The proportions of Transparent Epoxy resin is 100:25 or 4:1 – A:B by weight. You can always check that taking a look at the labels of the bottles – they are always printed there:)

For calculations we suggest using our app – GooglePlay & AppStore.

How to calculate, how much hardener do you need? Take your proportions –JUST AN EXAMPLE – 100:25. Then take the weight of component A and multiply on B, (if 100:25 – A*0.25; if 100:70 – A*0.70; if 100:87 – A*0.87).

So! If you have component A 5kg, and proportions 100:25 your calculation –

5*0.25=1.25kg of component B.

Q. Can I do 20cm per one casting?

A. Unfortunately:(

The maximum layer`s level is 10cm. If you need to cast more, do it steadily –

Do 10cm, then wait 6-10h and add next 10cm. Repeat, if needed, waiting 6-10h between layers.

Q. Why epoxy is murky?

A. Epoxy just become frozen during storage/delivery, etc. Please, don`t use that before you de-frost it fully, it may affect the result. Just put the component A into very hot water for 10-15 minutes. Repeat if needed.

Q. What`s the coverage of 1kg?

A. 1kg of mix epoxy+hardener covers area 30*30*1cm.

You can use our resin calculator here – 🔮LINK🔮

Or our app – GooglePlay & AppStore.

Q. What`s the volume 1kg resin+hardener?

A. 1kg epoxy resin ~ 0.9l

Just take the weight and divide at 1.1, you`ll get the volume in litres.

Q. Can I use epoxy at home?

A. Yeap, we recommend working in well ventilated area and use protective cloves and masks.

Q. What to use for colouring?

A. Of course we recommend using our tested pigments and colourants.

With other brands we suggest to make a small test before making large project.

The rules not so many – it has to be NOT water based and without high level of solvents. Please, be sure that the amount of colourants doesn`t exceed 5% from full mix.

Q. Do you have resin with higher viscosity?

A. Sure!

We have the next grade of resins by viscosity:

Super low viscosity (low type of resin) – “Epoxytable-5”;

Low viscosity – “Transparente”;

Medium viscosity – “Art Pro”;

High viscosity – “Art Pro Deluxe” ;

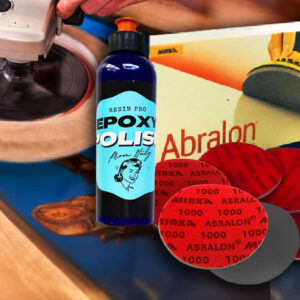

Q. What would you recommend for polishing my art-work?

A. We have a special kit for such tasks, take a look here –