On sale

“Flowstone” – Complete Permeable Floor Kit – Pebbles & Resin

Price range: £42.85 through £3,389.85

Sat, 7. Mar

Ordered

Sat, 7. Mar - Mon, 9. Mar

Order Shipped

Mon, 9. Mar - Tue, 10. Mar

Estimated delivery

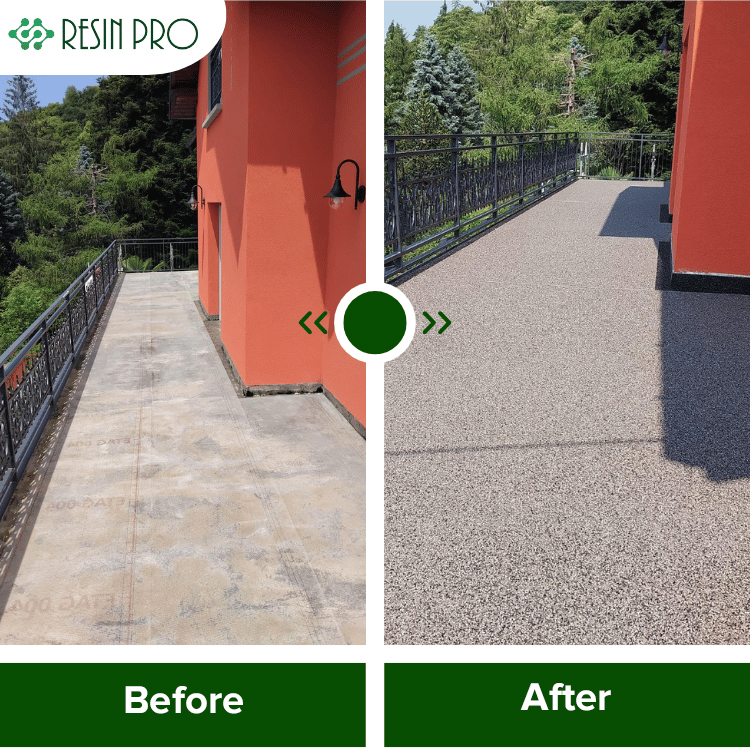

Upgrade your outdoor spaces with the Flowstone draining floor kit, a durable, permeable pebble and resin system designed for driveways, footpaths, and patios in the UK climate. Each kit is sized by surface area and includes detailed resin guidance: use non-yellowing polyurethane for white aggregates and low-yellowing epoxy for coloured stones to ensure lasting colour integrity.

- 🌱 Permeable solution: Allows water drainage, preventing puddles

- 💸 Cost-effective renewal: Easily restore and protect driveways and paths with included materials

- 🎨 Customisable finish: Wide selection of colours and granule sizes

- Simple application: Step-by-step guidance for all skill levels to ensure optimal results

Description

An innovative, easy and long-lasting solution for your outdoor spaces?

Here’s how to apply it

Our Colours:

Main Features:

Contacts

Technical Support: We are always available to guide you in choosing the right products and to help you throughout the process.

Phone: +44 7596 850968

Email: in**@******ro.eu

Stones & Binder Calculator

Stones: 0.00 kg

Resin binder: 0.00 kg

*Recommended minimum thickness for driveway: 2 cm; other areas: 1.5 cm.

Available Binders

Epoxy Binder: Offers exceptional strength and a glossy finish, ideal for surfaces that need to withstand heavy loads and intense traffic. NOT SUITABLE FOR WHITE CARRARA GRAVEL.

Polyurethane Binder: Ensures flexibility and durability, perfect for outdoor applications and surfaces subject to temperature variations. Suitable for all available gravel types.

- Creation of continuous, decorative, draining, non-slip, and drivable surfaces.

- Gravel effect flooring for a wide range of urban environments, including pool edges, bike paths, walkways, small roads, squares, balconies, terraces, common condominium areas, courtyards, and parking lots.

- Flooring for shopping centers and equipped public areas.

Application procedure for a perfect surface

WARNING:

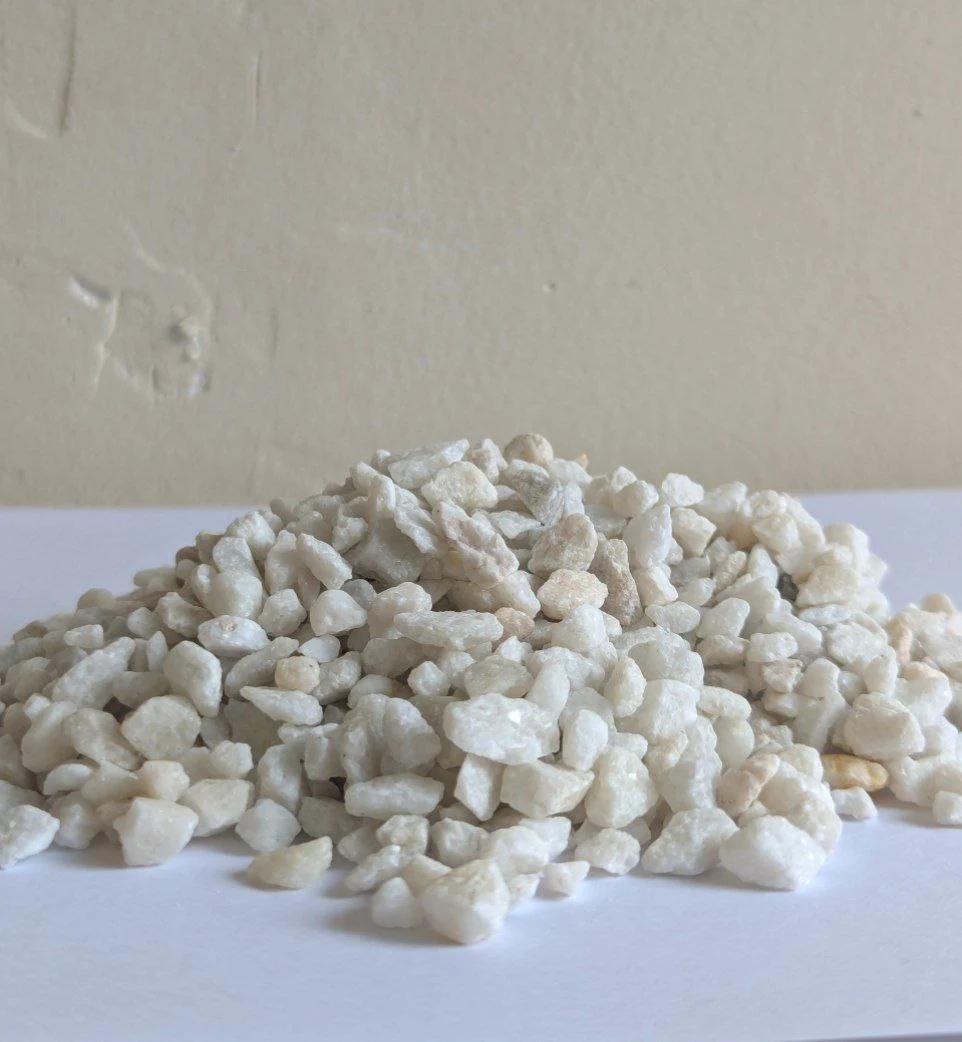

Based on the choice of stone/pebble colouring, you must select the most suitable binder to avoid compromising the colouring of the stone over time: follow our instructions for optimal results.

Remember: Epoxy binder should not be used with Bianco Carrara Pebble/Gravel.

Procedure:

- Choose Your Colouring: Select your preferred colouring from those available. Consider approximately 20-25 kg/sqm for optimal application; you will find everything you need in the ready-to-use ResinPro kits.

- Gravel Preparation: Our gravel is washed and dried, ready to use. The ResinPro gravel grain size is 4-8 mm: the most universal among those available. The minimal

- Substrate Preparation: Ensure the substrate is adequately prepared, clean, and free of impurities.

- Optional: For added safety, you can apply a coat of Transparent Epoxy Resin as a primer with a roller. Consider a consumption of 200 gr/sqm for this use. Dust the surface with quartz powder as soon as the resin is applied. Once the primer has fully cured, remove the excess quartz.

- Wait: If applying the primer, wait at least 8 hours before applying the gravel and resin layer; this time may vary depending on environmental conditions, especially temperature.

- If the substrate did not require primer, we are ready!

- Create Your Mix: Carefully weigh the chosen binder to add to the gravel; this phase is very important!

- For Epoxy Resin with Colored Gravel:

- 4-8 mm diameter – for 25 kg of gravel, add 750 gr of Transparent Epoxy Resin.

- For Polyurethane Resin with White/Clear Gravel:

- 4-8 mm diameter – for 25 kg of gravel, add 820 gr of Polyurethane Resin.

- Note: For the polyurethane binder, it is important to be precise in mixing the necessary amount before application, as excess binder can cause swelling and foaming. The correct amount of binder is just enough to wet the surface of the gravel without dripping.

- For Epoxy Resin with Colored Gravel:

If you have any doubts, contact our support team!

- Mix Thoroughly: Mix until the blend is “wet.”

- Application of the Mixture: Use a straightedge, rake, or recommended tool to evenly apply the mixture onto the surface to be decorated and coated, ensuring total coverage.

- Compaction of the Mixture: After application, compact the mixture layer with a trowel or a dedicated compactor, ensuring it is even and well-leveled.

- Surface Reinforcement: For greater surface strength, consider applying a coat of binder with a short-pile roller once the mixture is walkable (approximately 100-150 gr/sqm).

By following this procedure, you will ensure a decorative and durable surface, ready to be used and appreciated for a long time. If you have any doubts, contact our technical support: Contacts

Why Choose ResinPro:

- Technical Support: Our team of experts is available to guide you in product selection and provide assistance throughout the process.

- Guaranteed Quality: We use only high-quality materials to ensure excellent and lasting results.

Choose the quality and reliability of ResinPro kits to transform outdoor spaces with beautiful and functional long-lasting flooring.

Frequently Asked Questions

General

What types of resin do you offer for flooring?

We offer resins for industrial cement-based floors, coloured self-levelling floors, garage floors, permeable pebble flooring and tile coatings.

What are the advantages of resins compared to other flooring materials?

Resins offer high wear resistance, easy maintenance, durability, waterproofing and a highly customisable aesthetic.

Are specific weather conditions required for resin application?

Yes, resin application requires specific climatic conditions to ensure proper adhesion and curing. It is advisable to avoid very low or very high temperatures and high humidity.

Permeable Pebble Flooring

What is a permeable floor?

A permeable floor is a surface designed to allow rainwater to pass through it, preventing water stagnation and reducing the risk of flooding.

It is made of a special mix of granules and resin, allowing optimal water dispersion into the subsoil.

What are the advantages of a permeable floor?

- Attractive and customisable appearance

- Very low application costs

- Excellent water drainage

- Resistance to weather conditions and frost

- Anti-slip surface

- Low maintenance

- DIY installation possible

- Greater durability compared to traditional floors in areas with frequent rainfall

Where is it recommended to install a permeable floor?

- Outdoor areas subject to frequent rain

- Car parks and driveways

- Gardens and courtyards

- Pedestrian and cycle paths

- Public spaces such as squares and parks

- Shared areas such as terraces and yards

What materials are used to create a permeable floor?

- Selected, washed and dried granules

- Epoxy binder

How long does a complete application take?

Application is extremely fast: if applied in the morning (with at least 20°C), it will be walkable after around 12 hours for light foot traffic. Maximum hardness (suitable for vehicles) is achieved after approximately 36–48 hours (depending on ambient temperature). At higher temperatures, these times are significantly reduced, speeding up the curing process.

A person with no experience can apply about 5 sqm per hour, including preparation. The more applicators involved, the shorter the overall working time.

How is a permeable floor installed?

- Preparation of the existing solid substrate

- Laying of the permeable material (granule and resin mix)

- Compaction and levelling of the surface

- Sealing or surface treatment, if required

What maintenance is required?

Permeable flooring is very durable and does not require any special maintenance beyond that of a standard outdoor floor.

How long does a permeable floor last?

Its lifespan depends on the materials used and the maintenance carried out, but in general it can last for decades with proper care.

Are permeable floors eco-friendly?

Yes, they help manage rainwater more sustainably, reduce flood risk and can contribute to groundwater recharge.

What are the costs associated with installing a permeable floor?

Costs are generally very low and vary depending on the selected square metres and site conditions. The price for the ResinPro system starts from £42.85/sqm. Contact our technical support for a personalised quote.

Are permeable floors suitable for cold climates?

Yes, provided the installation is carried out correctly.

Can I install a permeable floor myself?

Absolutely. Application is simple and quick and does not require specific skills. For large surfaces, using a cement mixer is recommended to make mixing granules and resin easier.

Are permeable floors suitable for high-traffic areas?

Yes, granule and resin permeable floors are strong and suitable for pedestrian areas, driveways and car parks, provided appropriate materials and installation techniques are used.

Can it also be applied on compacted soil?

Yes, it is possible. For light traffic, a 2 cm layer is sufficient. For heavy vehicles, a concrete base of at least 7–8 cm is recommended, or the application of a grass-reinforcement grid with a thicker mix. Have doubts? Ask us how to do it!

What is the best time to apply permeable flooring?

The resin cures under a wide range of conditions. The recommended minimum temperature is 10°C and the maximum is 40°C. At higher temperatures, curing times are reduced.

What happens if the floor cracks?

If damage occurs, it is sufficient to apply a new resin roll or a fresh mix to restore the floor to like-new condition.

What should I pay attention to during application?

- Correct resin dosage

- Dry surfaces, as humidity and wet substrates are the enemies of resin

Can I use gravel or stones I already have at home?

Yes, but they must be washed and dried to avoid curing issues and aesthetic defects.

What will be delivered to my home after placing an order?

Depending on the quantity ordered, you will receive a box or a small pallet with all materials ready to use.

I’m afraid I won’t know how to apply the floor – what can I do?

Don’t worry: ResinPro offers remote assistance and video support. Application is simple – you just need to mix the resin and granules thoroughly.

Contacts

How can I contact you for further information?

You can contact us by email, phone or WhatsApp. All contact details are available on our contacts page.

Reviews

An innovative, easy and long-lasting solution for your outdoor spaces?

Here’s how to apply it

Our Colours:

Main Features:

Contacts

Technical Support: We are always available to guide you in choosing the right products and to help you throughout the process.

Phone: +44 7596 850968

Email: in**@******ro.eu

Stones & Binder Calculator

Stones: 0.00 kg

Resin binder: 0.00 kg

*Recommended minimum thickness for driveway: 2 cm; other areas: 1.5 cm.

Available Binders

Epoxy Binder: Offers exceptional strength and a glossy finish, ideal for surfaces that need to withstand heavy loads and intense traffic. NOT SUITABLE FOR WHITE CARRARA GRAVEL.

Polyurethane Binder: Ensures flexibility and durability, perfect for outdoor applications and surfaces subject to temperature variations. Suitable for all available gravel types.

- Creation of continuous, decorative, draining, non-slip, and drivable surfaces.

- Gravel effect flooring for a wide range of urban environments, including pool edges, bike paths, walkways, small roads, squares, balconies, terraces, common condominium areas, courtyards, and parking lots.

- Flooring for shopping centers and equipped public areas.

Application procedure for a perfect surface

WARNING:

Based on the choice of stone/pebble colouring, you must select the most suitable binder to avoid compromising the colouring of the stone over time: follow our instructions for optimal results.

Remember: Epoxy binder should not be used with Bianco Carrara Pebble/Gravel.

Procedure:

- Choose Your Colouring: Select your preferred colouring from those available. Consider approximately 20-25 kg/sqm for optimal application; you will find everything you need in the ready-to-use ResinPro kits.

- Gravel Preparation: Our gravel is washed and dried, ready to use. The ResinPro gravel grain size is 4-8 mm: the most universal among those available. The minimal

- Substrate Preparation: Ensure the substrate is adequately prepared, clean, and free of impurities.

- Optional: For added safety, you can apply a coat of Transparent Epoxy Resin as a primer with a roller. Consider a consumption of 200 gr/sqm for this use. Dust the surface with quartz powder as soon as the resin is applied. Once the primer has fully cured, remove the excess quartz.

- Wait: If applying the primer, wait at least 8 hours before applying the gravel and resin layer; this time may vary depending on environmental conditions, especially temperature.

- If the substrate did not require primer, we are ready!

- Create Your Mix: Carefully weigh the chosen binder to add to the gravel; this phase is very important!

- For Epoxy Resin with Colored Gravel:

- 4-8 mm diameter – for 25 kg of gravel, add 750 gr of Transparent Epoxy Resin.

- For Polyurethane Resin with White/Clear Gravel:

- 4-8 mm diameter – for 25 kg of gravel, add 820 gr of Polyurethane Resin.

- Note: For the polyurethane binder, it is important to be precise in mixing the necessary amount before application, as excess binder can cause swelling and foaming. The correct amount of binder is just enough to wet the surface of the gravel without dripping.

- For Epoxy Resin with Colored Gravel:

If you have any doubts, contact our support team!

- Mix Thoroughly: Mix until the blend is “wet.”

- Application of the Mixture: Use a straightedge, rake, or recommended tool to evenly apply the mixture onto the surface to be decorated and coated, ensuring total coverage.

- Compaction of the Mixture: After application, compact the mixture layer with a trowel or a dedicated compactor, ensuring it is even and well-leveled.

- Surface Reinforcement: For greater surface strength, consider applying a coat of binder with a short-pile roller once the mixture is walkable (approximately 100-150 gr/sqm).

By following this procedure, you will ensure a decorative and durable surface, ready to be used and appreciated for a long time. If you have any doubts, contact our technical support: Contacts

Why Choose ResinPro:

- Technical Support: Our team of experts is available to guide you in product selection and provide assistance throughout the process.

- Guaranteed Quality: We use only high-quality materials to ensure excellent and lasting results.

Choose the quality and reliability of ResinPro kits to transform outdoor spaces with beautiful and functional long-lasting flooring.

Frequently Asked Questions

General

What types of resin do you offer for flooring?

We offer resins for industrial cement-based floors, coloured self-levelling floors, garage floors, permeable pebble flooring and tile coatings.

What are the advantages of resins compared to other flooring materials?

Resins offer high wear resistance, easy maintenance, durability, waterproofing and a highly customisable aesthetic.

Are specific weather conditions required for resin application?

Yes, resin application requires specific climatic conditions to ensure proper adhesion and curing. It is advisable to avoid very low or very high temperatures and high humidity.

Permeable Pebble Flooring

What is a permeable floor?

A permeable floor is a surface designed to allow rainwater to pass through it, preventing water stagnation and reducing the risk of flooding.

It is made of a special mix of granules and resin, allowing optimal water dispersion into the subsoil.

What are the advantages of a permeable floor?

- Attractive and customisable appearance

- Very low application costs

- Excellent water drainage

- Resistance to weather conditions and frost

- Anti-slip surface

- Low maintenance

- DIY installation possible

- Greater durability compared to traditional floors in areas with frequent rainfall

Where is it recommended to install a permeable floor?

- Outdoor areas subject to frequent rain

- Car parks and driveways

- Gardens and courtyards

- Pedestrian and cycle paths

- Public spaces such as squares and parks

- Shared areas such as terraces and yards

What materials are used to create a permeable floor?

- Selected, washed and dried granules

- Epoxy binder

How long does a complete application take?

Application is extremely fast: if applied in the morning (with at least 20°C), it will be walkable after around 12 hours for light foot traffic. Maximum hardness (suitable for vehicles) is achieved after approximately 36–48 hours (depending on ambient temperature). At higher temperatures, these times are significantly reduced, speeding up the curing process.

A person with no experience can apply about 5 sqm per hour, including preparation. The more applicators involved, the shorter the overall working time.

How is a permeable floor installed?

- Preparation of the existing solid substrate

- Laying of the permeable material (granule and resin mix)

- Compaction and levelling of the surface

- Sealing or surface treatment, if required

What maintenance is required?

Permeable flooring is very durable and does not require any special maintenance beyond that of a standard outdoor floor.

How long does a permeable floor last?

Its lifespan depends on the materials used and the maintenance carried out, but in general it can last for decades with proper care.

Are permeable floors eco-friendly?

Yes, they help manage rainwater more sustainably, reduce flood risk and can contribute to groundwater recharge.

What are the costs associated with installing a permeable floor?

Costs are generally very low and vary depending on the selected square metres and site conditions. The price for the ResinPro system starts from £42.85/sqm. Contact our technical support for a personalised quote.

Are permeable floors suitable for cold climates?

Yes, provided the installation is carried out correctly.

Can I install a permeable floor myself?

Absolutely. Application is simple and quick and does not require specific skills. For large surfaces, using a cement mixer is recommended to make mixing granules and resin easier.

Are permeable floors suitable for high-traffic areas?

Yes, granule and resin permeable floors are strong and suitable for pedestrian areas, driveways and car parks, provided appropriate materials and installation techniques are used.

Can it also be applied on compacted soil?

Yes, it is possible. For light traffic, a 2 cm layer is sufficient. For heavy vehicles, a concrete base of at least 7–8 cm is recommended, or the application of a grass-reinforcement grid with a thicker mix. Have doubts? Ask us how to do it!

What is the best time to apply permeable flooring?

The resin cures under a wide range of conditions. The recommended minimum temperature is 10°C and the maximum is 40°C. At higher temperatures, curing times are reduced.

What happens if the floor cracks?

If damage occurs, it is sufficient to apply a new resin roll or a fresh mix to restore the floor to like-new condition.

What should I pay attention to during application?

- Correct resin dosage

- Dry surfaces, as humidity and wet substrates are the enemies of resin

Can I use gravel or stones I already have at home?

Yes, but they must be washed and dried to avoid curing issues and aesthetic defects.

What will be delivered to my home after placing an order?

Depending on the quantity ordered, you will receive a box or a small pallet with all materials ready to use.

I’m afraid I won’t know how to apply the floor – what can I do?

Don’t worry: ResinPro offers remote assistance and video support. Application is simple – you just need to mix the resin and granules thoroughly.

Contacts

How can I contact you for further information?

You can contact us by email, phone or WhatsApp. All contact details are available on our contacts page.

COD:

kit-per-pavimenti-drenanti-2

Google

Google