“Epoxyprimer” – Universal Water-Based Floor Primer

Price range: £148.84 through £272.45

Fri, 27. Feb

Ordered

Fri, 27. Feb - Mon, 2. Mar

Order Shipped

Mon, 2. Mar - Tue, 3. Mar

Estimated delivery

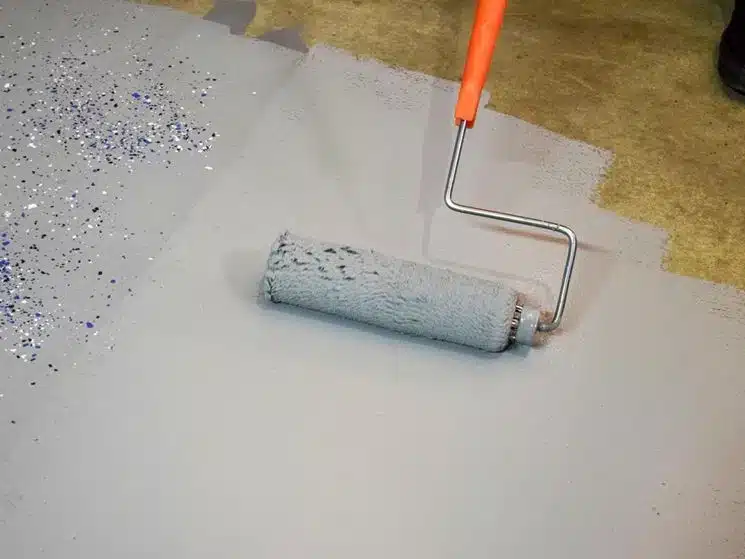

Epoxyprimer is a universal water-based two-component epoxy resin floor primer (mixing ratio 100:40), formulated to deliver reliable adhesion and long-lasting durability for epoxy flooring projects. Ideal for professionals, resin artists, and DIYers working with concrete, ceramic, screed, tiles, or timber surfaces. It requires 24–48 hours for full cure and has a consumption rate of 100–300 g/m² depending on substrate porosity.

- 💪 Superior adhesion: Maximises bonding between substrates and epoxy resin coatings

- 🌱 Eco-friendly & odourless: Safe for indoor use, free from harmful fumes

- 🏡 Versatile compatibility: Suitable for concrete, wood, tiles, and screeds

- 🎨 Simple application: Roller, brush, or spatula for smooth, consistent results

Description

💥 About

Epoxyprimer is a universal water-based floor primer designed for strong, lasting adhesion in epoxy resin flooring systems. This high-performance primer offers exceptional bonding on concrete, ceramic tiles, screeds, and timber, making it a trusted choice for resin professionals, DIY enthusiasts, and resin artists aiming for reliable, durable results. Particularly suited as the foundation for epoxy resin coatings, Epoxyprimer ensures your floor finish remains stable and resistant to lifting or peeling.

💡 Key Benefits

- Enhanced adhesion Maximises bond between epoxy resin layers and substrates, preventing failure 💪

- Universal compatibility Works with concrete, timber, screeds, and ceramic tiles, saving preparation time 🏡

- Odourless and safe Water-based formula is eco-friendly, fume-free and comfortable for indoor use 🌱

- Effortless application Even coverage with roller, brush, or spatula makes preparation quick and easy 🎨

☝🏽 Useful Information

- Mixing ratio 100:40 by weight delivers optimal performance

- Curing time Allow 24–48 hours at room temperature for full cure

- Coverage 100g–300g/m², adjustable for surface porosity

- Multiple coats Apply a second coat for uneven floors if required

🎯 Who It’s For

- – Resin artists and crafters

- – Hobbyists and DIY enthusiasts

- – Flooring professionals

Choose Epoxyprimer for reliable preparation of surfaces prior to epoxy resin flooring. Trust its quality for decorative, industrial, or artistic applications where adhesion and durability matter most.

Instruction

Freshly made surfaces (screeds/ concrete / cements):

Allow the surface to mature for at least 4 weeks and make sure that no additives such as waxes and silicones have been used in the finishing layer. Scrape off any non-adhered lumps and dust well with a vacuum cleaner.

Check that the floor is dry and that there are no signs of capillary moisture rising from the subfloor. The application is not recommended with relative humidity above 15%. To improve the anchoring of the epoxy, it is advisable to treat the substrate with a 10% solution of muriatic acid, leaving it to act until the typical bubbles on the surface are no longer visible. Then rinse thoroughly with water and allow to dry completely before proceeding to application.

Already painted surfaces:

Carefully check the rising humidity as in the case of new surfaces (see humidity specified above). Carefully remove any greasy and greasy stains. These must be removed with suitable detergents. Rinse immediately.

On particularly dusty substrates or floors with obvious chalking of the substrate, a preventive consolidating treatment is recommended by applying a specific water primer.

In the case of floors already in use, which are particularly dirty, it is advisable to treat the surface with a solution of muriatic acid as described above. In case of imported rising humidity, our team is available to advise you (contact section).

In case of damaged/irregular floors (cracks or missing parts)first make any grouting with Epoxy Putty – MAGELSTIC

Reviews

💥 About

Epoxyprimer is a universal water-based floor primer designed for strong, lasting adhesion in epoxy resin flooring systems. This high-performance primer offers exceptional bonding on concrete, ceramic tiles, screeds, and timber, making it a trusted choice for resin professionals, DIY enthusiasts, and resin artists aiming for reliable, durable results. Particularly suited as the foundation for epoxy resin coatings, Epoxyprimer ensures your floor finish remains stable and resistant to lifting or peeling.

💡 Key Benefits

- Enhanced adhesion Maximises bond between epoxy resin layers and substrates, preventing failure 💪

- Universal compatibility Works with concrete, timber, screeds, and ceramic tiles, saving preparation time 🏡

- Odourless and safe Water-based formula is eco-friendly, fume-free and comfortable for indoor use 🌱

- Effortless application Even coverage with roller, brush, or spatula makes preparation quick and easy 🎨

☝🏽 Useful Information

- Mixing ratio 100:40 by weight delivers optimal performance

- Curing time Allow 24–48 hours at room temperature for full cure

- Coverage 100g–300g/m², adjustable for surface porosity

- Multiple coats Apply a second coat for uneven floors if required

🎯 Who It’s For

- – Resin artists and crafters

- – Hobbyists and DIY enthusiasts

- – Flooring professionals

Choose Epoxyprimer for reliable preparation of surfaces prior to epoxy resin flooring. Trust its quality for decorative, industrial, or artistic applications where adhesion and durability matter most.

Freshly made surfaces (screeds/ concrete / cements):

Allow the surface to mature for at least 4 weeks and make sure that no additives such as waxes and silicones have been used in the finishing layer. Scrape off any non-adhered lumps and dust well with a vacuum cleaner.

Check that the floor is dry and that there are no signs of capillary moisture rising from the subfloor. The application is not recommended with relative humidity above 15%. To improve the anchoring of the epoxy, it is advisable to treat the substrate with a 10% solution of muriatic acid, leaving it to act until the typical bubbles on the surface are no longer visible. Then rinse thoroughly with water and allow to dry completely before proceeding to application.

Already painted surfaces:

Carefully check the rising humidity as in the case of new surfaces (see humidity specified above). Carefully remove any greasy and greasy stains. These must be removed with suitable detergents. Rinse immediately.

On particularly dusty substrates or floors with obvious chalking of the substrate, a preventive consolidating treatment is recommended by applying a specific water primer.

In the case of floors already in use, which are particularly dirty, it is advisable to treat the surface with a solution of muriatic acid as described above. In case of imported rising humidity, our team is available to advise you (contact section).

In case of damaged/irregular floors (cracks or missing parts)first make any grouting with Epoxy Putty – MAGELSTIC

COD:

epoxyprimerfamily

Google

Google