On sale

“ICreation” – Fast Epoxy Resin – 6h Demoulding Time

Price range: £19.40 through £52.85

Fri, 27. Feb

Ordered

Fri, 27. Feb - Mon, 2. Mar

Order Shipped

Mon, 2. Mar - Tue, 3. Mar

Estimated delivery

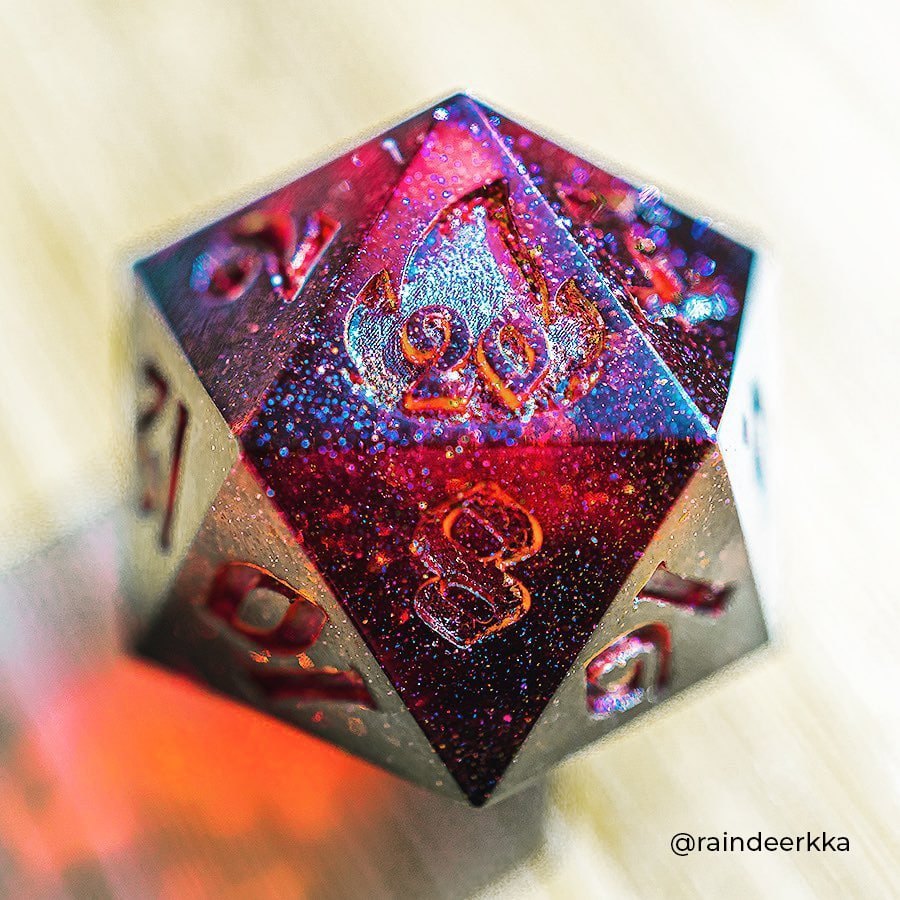

ICREATION fast epoxy resin offers super-fast catalysis with a 6-hour demoulding time and 12-hour full cure, ideal for artists and crafters needing rapid, time-critical results. This transparent, glossy two-part resin delivers a crystal-clear, self-levelling surface perfect for jewellery making, art, and decorative crafts.

- 🕒 6-hour demoulding time – speed up your workflow

- ✨ Crystal-clear, glossy, and self-levelling finish for professional effects

- 🧴 Easy 2:1 mixing ratio simplifies preparation

- 🌞 UV filter protection prevents yellowing

Perfect for experienced creators and hobbyists looking to achieve quality, durable results with less waiting time.

Description

💥 About

ICREATION Fast Epoxy Resin is designed for creators who want exceptional results without long waits. This quick-curing resin mix is perfect for resin art, epoxy jewellery, encapsulating objects, and bespoke craft projects. With its 6-hour demoulding and 12-hour full cure times, it’s a time-saving choice for both professionals and hobbyists.

💡 Key Benefits

- Super-fast catalysis – Ready to demould in just 6 hours, with full cure in 12h 🕒

- High transparency – Achieve a real liquid crystal-look finish ✨

- Self-levelling glossy surface – Professional-quality shine every time 💎

- UV filter – Protects against yellowing for lasting clarity 🌞

☝🏽 Useful Information

- Mixing ratio: Simple 2:1 (resin:hardener)

- Non-toxic, cruelty-free & vegan-friendly: Safe for artists

- Versatile use: Ideal for jewellery, casting, coating, and encapsulation

🎯 Who It’s For

- – Resin artists and crafters

- – Hobbyists and DIY enthusiasts

- – Professional makers needing fast, reliable resin results

Choose ICREATION Fast Epoxy Resin for efficient, high-quality results in your epoxy resin craft projects. Trusted for clarity, ease, and durability.

Technical data

TECHNICAL DATA

“ICREATION” – Fast Epoxy Resin – 6h Demoulding Time:

- Mix ratio: 2:1 by weight

- Pot-life: (150 gr at 30°C) [0,33 lb at 86 F]: 0h10 ′

- Viscosity: Resin – mPas 800-700; Hardener – 300-200; Mix – 500

- Full catalysis: 12h

- Demoulding time: 6h

- Film catalysis (1.5 mm at 30°C) [0,05” at 86 F]: 3h 00 ′

- Maximum pouring level: 1.5cm*

- Minimum pouring level: 1.5mm

- Heat resistance: up to 70°C

- Coverage 1kg: 100*60*0.15cm

- 1sqm consumption (1.5mm thickness): 5kg

* – may vary from the pouring`s conditions (please, read instruction).

If you have not enough experience, we insistly suggest to make a small test before working with large project.

Main features:

Fast reaction / Easy mixing ratio / Excellent transparency / UV stable

Applications:

DIY / Coating up to 1.5 cm / Jewellery settings / Modelling / Artistic creations / Lamination / Adhesive / General coating system

Instruction

If you are working with resin for the first time, we recommend reading our articles first:

–How to use epoxy resin: tricks and general guide

–How to calculate the quantity of a and b in epoxy resins

Epoxy resin is mixed according to the proportions unique for each type, specified in the technical specifications. Each component is measured strictly by weight in grams (in the case of using weight proportions), both components are poured into one container (clean and dry) and mixed for 5-7 minutes (alternating stirring clockwise and counterclockwise, whilst ensuring that the mixture is scraped from the walls and bottom of the container). After mixing, it is recommended to pour the mixture into another clean and dry container and leave for 5-7 minutes. After that, the resin can be poured into a silicone mould, into a homemade formwork.

Work with epoxy resin in a well-ventilated/ ventilated room with (important!) low humidity at a temperature not lower than +20 and not higher than +25-27 °C. Moisture should not be in the moulds / blanks, otherwise cloudy stains and other defects may appear on the surface of the product after curing. It is not recommended to work with resin during and after rain, near reservoirs, when foggy.

When working with the product, use personal protective equipment: a respirator mask, gloves, and safety glasses.

Do not leave a large amount (more than 100 g at t +25 °C) of mixed resin in one container for more than 10 minutes. To avoid overheating of the resin caused by the “mass” effect, pour the mixture into other, smaller containers.

Add no more than 5% of dyes, pigments and other additives to the finished mixture. In no case should you add water-based dyes to the epoxy resin.

Keep track of the operating time: the “life” time of the resin is indicated in the technical specifications of the product. After this time, the mixture will begin to thicken and heat up.

Do not use this resin for large fillings, it is only used to create jewellery. Do not mix a large amount (more than 100-150 grams) of the product at a time.

WARNINGS:

During processing, use protective masks, gloves, and other protective clothing.

In case of contact with eyes, immediately rinse with cold water for 15 minutes and immediately consult a doctor.

Safety precautions

Keeping:

Store the product in tightly closed containers at room temperature in a dry, sun-proof place and out of the reach of children.

If the original packaging is damaged, each component can be poured into a separate clean and dry container with tightly closed lids. Ensure you use protective equipment when doing this.

Using:

In liquid form, the product is dangerous to humans and the environment. Avoid contact of the material in liquid form with the skin, mucous membranes, respiratory and digestive organs. Do not drink, eat or smoke during use, or during the time of complete catalysis, whilst in the same room as the product.

No one is immune from allergies, despite the fact that this is a rare phenomenon. If a skin rash appears during work, stop working with resin and consult a doctor.

Be sure to use personal protective equipment when working with resin!

We repeat, when working with the material, use personal protective equipment for the skin, mucous membranes of the eyes, and respiratory organs. The work of minors and pregnant women with the material is not recommended and strongly discouraged.

Do not work with the product near sources of flame, sparks etc.

Do not allow moisture or water-based additives to enter the liquid product.

Disposal:

Do not allow liquid material to enter the sewer and the environment. For disposal, it is necessary to harden unnecessary material residues and dispose only in containers for polymer materials. To dispose of components in liquid form, as well as containers with their residues, contact specialised companies or industrial waste collection points.

Reviews

💥 About

ICREATION Fast Epoxy Resin is designed for creators who want exceptional results without long waits. This quick-curing resin mix is perfect for resin art, epoxy jewellery, encapsulating objects, and bespoke craft projects. With its 6-hour demoulding and 12-hour full cure times, it’s a time-saving choice for both professionals and hobbyists.

💡 Key Benefits

- Super-fast catalysis – Ready to demould in just 6 hours, with full cure in 12h 🕒

- High transparency – Achieve a real liquid crystal-look finish ✨

- Self-levelling glossy surface – Professional-quality shine every time 💎

- UV filter – Protects against yellowing for lasting clarity 🌞

☝🏽 Useful Information

- Mixing ratio: Simple 2:1 (resin:hardener)

- Non-toxic, cruelty-free & vegan-friendly: Safe for artists

- Versatile use: Ideal for jewellery, casting, coating, and encapsulation

🎯 Who It’s For

- – Resin artists and crafters

- – Hobbyists and DIY enthusiasts

- – Professional makers needing fast, reliable resin results

Choose ICREATION Fast Epoxy Resin for efficient, high-quality results in your epoxy resin craft projects. Trusted for clarity, ease, and durability.

TECHNICAL DATA

“ICREATION” – Fast Epoxy Resin – 6h Demoulding Time:

- Mix ratio: 2:1 by weight

- Pot-life: (150 gr at 30°C) [0,33 lb at 86 F]: 0h10 ′

- Viscosity: Resin – mPas 800-700; Hardener – 300-200; Mix – 500

- Full catalysis: 12h

- Demoulding time: 6h

- Film catalysis (1.5 mm at 30°C) [0,05” at 86 F]: 3h 00 ′

- Maximum pouring level: 1.5cm*

- Minimum pouring level: 1.5mm

- Heat resistance: up to 70°C

- Coverage 1kg: 100*60*0.15cm

- 1sqm consumption (1.5mm thickness): 5kg

* – may vary from the pouring`s conditions (please, read instruction).

If you have not enough experience, we insistly suggest to make a small test before working with large project.

Main features:

Fast reaction / Easy mixing ratio / Excellent transparency / UV stable

Applications:

DIY / Coating up to 1.5 cm / Jewellery settings / Modelling / Artistic creations / Lamination / Adhesive / General coating system

If you are working with resin for the first time, we recommend reading our articles first:

–How to use epoxy resin: tricks and general guide

–How to calculate the quantity of a and b in epoxy resins

Epoxy resin is mixed according to the proportions unique for each type, specified in the technical specifications. Each component is measured strictly by weight in grams (in the case of using weight proportions), both components are poured into one container (clean and dry) and mixed for 5-7 minutes (alternating stirring clockwise and counterclockwise, whilst ensuring that the mixture is scraped from the walls and bottom of the container). After mixing, it is recommended to pour the mixture into another clean and dry container and leave for 5-7 minutes. After that, the resin can be poured into a silicone mould, into a homemade formwork.

Work with epoxy resin in a well-ventilated/ ventilated room with (important!) low humidity at a temperature not lower than +20 and not higher than +25-27 °C. Moisture should not be in the moulds / blanks, otherwise cloudy stains and other defects may appear on the surface of the product after curing. It is not recommended to work with resin during and after rain, near reservoirs, when foggy.

When working with the product, use personal protective equipment: a respirator mask, gloves, and safety glasses.

Do not leave a large amount (more than 100 g at t +25 °C) of mixed resin in one container for more than 10 minutes. To avoid overheating of the resin caused by the “mass” effect, pour the mixture into other, smaller containers.

Add no more than 5% of dyes, pigments and other additives to the finished mixture. In no case should you add water-based dyes to the epoxy resin.

Keep track of the operating time: the “life” time of the resin is indicated in the technical specifications of the product. After this time, the mixture will begin to thicken and heat up.

Do not use this resin for large fillings, it is only used to create jewellery. Do not mix a large amount (more than 100-150 grams) of the product at a time.

WARNINGS:

During processing, use protective masks, gloves, and other protective clothing.

In case of contact with eyes, immediately rinse with cold water for 15 minutes and immediately consult a doctor.

Keeping:

Store the product in tightly closed containers at room temperature in a dry, sun-proof place and out of the reach of children.

If the original packaging is damaged, each component can be poured into a separate clean and dry container with tightly closed lids. Ensure you use protective equipment when doing this.

Using:

In liquid form, the product is dangerous to humans and the environment. Avoid contact of the material in liquid form with the skin, mucous membranes, respiratory and digestive organs. Do not drink, eat or smoke during use, or during the time of complete catalysis, whilst in the same room as the product.

No one is immune from allergies, despite the fact that this is a rare phenomenon. If a skin rash appears during work, stop working with resin and consult a doctor.

Be sure to use personal protective equipment when working with resin!

We repeat, when working with the material, use personal protective equipment for the skin, mucous membranes of the eyes, and respiratory organs. The work of minors and pregnant women with the material is not recommended and strongly discouraged.

Do not work with the product near sources of flame, sparks etc.

Do not allow moisture or water-based additives to enter the liquid product.

Disposal:

Do not allow liquid material to enter the sewer and the environment. For disposal, it is necessary to harden unnecessary material residues and dispose only in containers for polymer materials. To dispose of components in liquid form, as well as containers with their residues, contact specialised companies or industrial waste collection points.

COD:

MQ-04H3-O5MA222

Google

Google