On sale

“NatuResin” – Mineral Resin & Water System

Price range: £17.85 through £99.85

Thu, 26. Feb

Ordered

Thu, 26. Feb - Fri, 27. Feb

Order Shipped

Fri, 27. Feb - Mon, 2. Mar

Estimated delivery

Natu🍀Resin is an innovative single-component mineral resin mixed with water, designed for crafters, artists, and makers seeking a safe alternative to traditional casting compounds. Ideal for creative projects such as coasters, trays, flower pots, and decorative items, this non-toxic solution delivers professional results with minimal effort.

- 🍀 Eco-friendly & VOC-free mineral resin formula

- ♻️ Solvent-free and safe – no gloves required

- 💎 Ceramic-like hardness for indoor & outdoor use

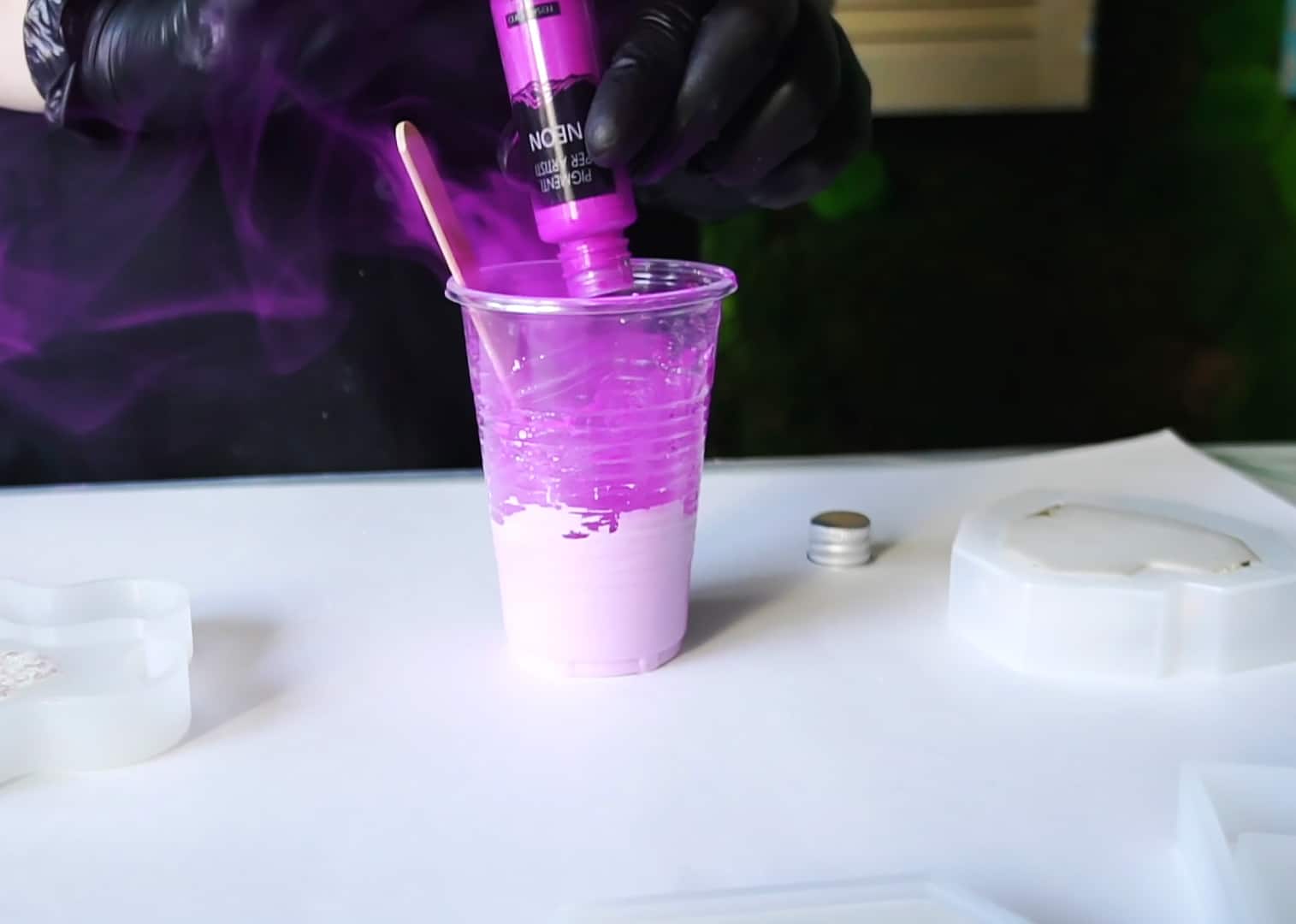

- 🎨 Customisable with pigments & paints after curing

Description

💥 About

NatuResin single-component mineral resin is an innovative water-activated system for artists, crafters, and DIY enthusiasts who require safe, eco-friendly casting materials. Suitable for creating striking coasters, trays, flower pots, candle holders, and more, it hardens to a ceramic-like finish, delivering high quality and durability for decorative projects. Formulated for mineral resin art and modelling, it is perfect for both indoor and outdoor applications.

💡 Key Benefits

- Non-toxic, VOC-free – Safe for any workspace and user peace of mind 🌱

- Solvent-free & easy to handle – Mix with tap water, no gloves needed ♻️

- Durable ceramic-like finish – Weather-resistant, suitable inside and outdoors 💎

- Customisable – Compatible with Resin Pro pigments and can be painted once cured 🎨

☝🏽 Useful Information

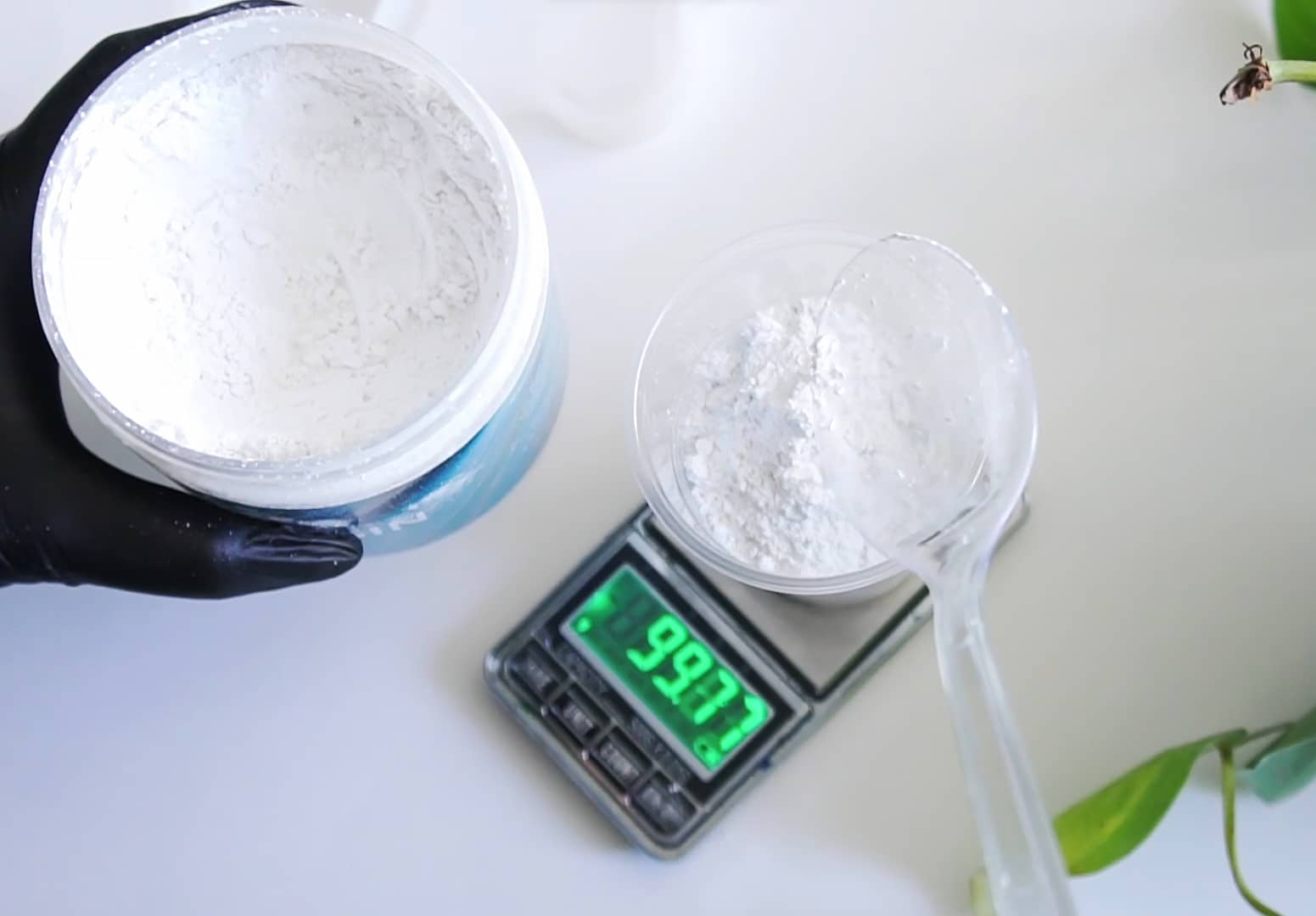

- Mixing: Only Part A (acrylic polymer) is included—add tap water to activate

- Usage: Use in silicone moulds for decorative items

- Finish: Glossy only where in contact with mould; otherwise matt

🎯 Who It’s For

- – Resin artists and crafters

- – Hobbyists and DIY enthusiasts

- – Small business owners making unique decor

Get creative with NatuResin and explore versatile mineral resin casting for your projects.

Technical data

TECHNICAL DATA

“NatuResin” – Mineral Resin & Water System:

- Mix ratio: 100:27 by weight – Gypsum/Water

- Working time: (25°C): 10-12 minutes

- Demoulding time: 18-20 minutes

- Full catalysis: 10 hours (depends on the thickness, shape of the product and the temperature of the medium)*

- Maximum pouring level: not limited

- Heat resistance after full curing time: 80 °C

- Coverage 1kg: 100*60*0.15cm

- 1sqm consumption (1.5mm thickness): 5kg

* The product will be solid in 15-20 minutes after pouring, but in the next 15 hours the strength of the material will increase.

Instruction

Mix the material and water in a ratio of 100 to 27 by weight. To understand how much water you need for a certain amount of gypsum, multiply the weight of gypsum by 0.27. For example, 150 grams (gypsum) multiply by 0.27 = 41 grams of water. Total: for 150 grams of gypsum, 41 grams of water is needed. Mix the mixture thoroughly for 2-4 minutes until any lumps disappear. For high–quality mixing, it is recommended to add the product to the water, and not vice versa, and the mixing itself should be intensive at first, then slower.

Carry out the filling carefully to the highest place in the mould to reduce the number of air bubbles in the mass due Technical specifications:

The product can be removed from the mould after 20-30 minutes after pouring and left to gain strength in a ventilated room for another 8-15 hours: after this time, the material will become much stronger and will be resistant to water even with prolonged contact.

The material can be coloured after mixing with water, however, we recommend using powder pigments so that the colour is uniform. Classic liquid dyes for epoxy resin may not mix well in the material. Finished products can also be covered with paint (acrylic, oil, etc.)

The use of large fillers is undesirable.

Formulas are relevant only for NatuResin! The composite of another manufacturer will be different.

The weight of the finished powder-water mixture:

length (cm) * width (cm) * height (cm) * 1.75 = weight of the powder-water mixture in grams

Example: 10 cm * 15 cm * 2 cm * 1.75 = 525 g of powder mixture with water

This means that 525 g of the mixture is needed for filling with a width of 10 cm, a length of 15 cm and a height of 2 cm

Separate weight of powder and water, knowing the weight of the finished mixture:

The weight of the mixture is divided by 1.27 = the weight of the powder

Water weight = powder weight * 0.27

Example: 525 g / 1.27 = 413 g of powder

413 g * 0.27 = 111.5 g of water (can be rounded up to 115 g)

Total: 413 + 111.5 = 524.5 g of the mixture

FAQs

FAQs

“NatuResin” – Mineral Resin & Water System:

Q.Can I use Naturesin with epoxy resin?

A.We recommend adding a layer of epoxy resin after the full curing time of the Naturesin (4-15h).

Q.What is the material used for Naturesin?

A.Naturesin is a non-toxic white powder that is mixed with water to create castings in silicone or polyurethane moulds.

Q.Does Naturesin have a maximum or minimum layer to avoid overheating?

A.No, Naturesin is made of natural materials, so you can make even large sculptures and there will be no chemical reaction.

Q.How to calculate the required weight?

A.Mix the material and water in a ratio of 100 to 27 by weight. To understand how much water you need for a certain amount of gypsum, multiply the weight of gypsum by 0.27. For example, 150 grams (gypsum) multiply by 0.27 = 41 grams of water. Total: for 150 grams of gypsum, 41 grams of water is needed.

Q.What are the proportions of Naturesin?

A.Mixing proportions with water (by weight): 100 (gypsum) to 27 (water).

Q.How can I colour Naturesin?

A.The material can be coloured after mixing with water, however, we recommend using powder pigments so that the colour is uniform. Classic liquid dyes for epoxy resin may not mix well in the material. Finished products can also be covered with paint (acrylic, oil, etc).

The use of large fillers is undesirable.

Reviews

💥 About

NatuResin single-component mineral resin is an innovative water-activated system for artists, crafters, and DIY enthusiasts who require safe, eco-friendly casting materials. Suitable for creating striking coasters, trays, flower pots, candle holders, and more, it hardens to a ceramic-like finish, delivering high quality and durability for decorative projects. Formulated for mineral resin art and modelling, it is perfect for both indoor and outdoor applications.

💡 Key Benefits

- Non-toxic, VOC-free – Safe for any workspace and user peace of mind 🌱

- Solvent-free & easy to handle – Mix with tap water, no gloves needed ♻️

- Durable ceramic-like finish – Weather-resistant, suitable inside and outdoors 💎

- Customisable – Compatible with Resin Pro pigments and can be painted once cured 🎨

☝🏽 Useful Information

- Mixing: Only Part A (acrylic polymer) is included—add tap water to activate

- Usage: Use in silicone moulds for decorative items

- Finish: Glossy only where in contact with mould; otherwise matt

🎯 Who It’s For

- – Resin artists and crafters

- – Hobbyists and DIY enthusiasts

- – Small business owners making unique decor

Get creative with NatuResin and explore versatile mineral resin casting for your projects.

TECHNICAL DATA

“NatuResin” – Mineral Resin & Water System:

- Mix ratio: 100:27 by weight – Gypsum/Water

- Working time: (25°C): 10-12 minutes

- Demoulding time: 18-20 minutes

- Full catalysis: 10 hours (depends on the thickness, shape of the product and the temperature of the medium)*

- Maximum pouring level: not limited

- Heat resistance after full curing time: 80 °C

- Coverage 1kg: 100*60*0.15cm

- 1sqm consumption (1.5mm thickness): 5kg

* The product will be solid in 15-20 minutes after pouring, but in the next 15 hours the strength of the material will increase.

Mix the material and water in a ratio of 100 to 27 by weight. To understand how much water you need for a certain amount of gypsum, multiply the weight of gypsum by 0.27. For example, 150 grams (gypsum) multiply by 0.27 = 41 grams of water. Total: for 150 grams of gypsum, 41 grams of water is needed. Mix the mixture thoroughly for 2-4 minutes until any lumps disappear. For high–quality mixing, it is recommended to add the product to the water, and not vice versa, and the mixing itself should be intensive at first, then slower.

Carry out the filling carefully to the highest place in the mould to reduce the number of air bubbles in the mass due Technical specifications:

The product can be removed from the mould after 20-30 minutes after pouring and left to gain strength in a ventilated room for another 8-15 hours: after this time, the material will become much stronger and will be resistant to water even with prolonged contact.

The material can be coloured after mixing with water, however, we recommend using powder pigments so that the colour is uniform. Classic liquid dyes for epoxy resin may not mix well in the material. Finished products can also be covered with paint (acrylic, oil, etc.)

The use of large fillers is undesirable.

Formulas are relevant only for NatuResin! The composite of another manufacturer will be different.

The weight of the finished powder-water mixture:

length (cm) * width (cm) * height (cm) * 1.75 = weight of the powder-water mixture in grams

Example: 10 cm * 15 cm * 2 cm * 1.75 = 525 g of powder mixture with water

This means that 525 g of the mixture is needed for filling with a width of 10 cm, a length of 15 cm and a height of 2 cm

Separate weight of powder and water, knowing the weight of the finished mixture:

The weight of the mixture is divided by 1.27 = the weight of the powder

Water weight = powder weight * 0.27

Example: 525 g / 1.27 = 413 g of powder

413 g * 0.27 = 111.5 g of water (can be rounded up to 115 g)

Total: 413 + 111.5 = 524.5 g of the mixture

FAQs

“NatuResin” – Mineral Resin & Water System:

Q.Can I use Naturesin with epoxy resin?

A.We recommend adding a layer of epoxy resin after the full curing time of the Naturesin (4-15h).

Q.What is the material used for Naturesin?

A.Naturesin is a non-toxic white powder that is mixed with water to create castings in silicone or polyurethane moulds.

Q.Does Naturesin have a maximum or minimum layer to avoid overheating?

A.No, Naturesin is made of natural materials, so you can make even large sculptures and there will be no chemical reaction.

Q.How to calculate the required weight?

A.Mix the material and water in a ratio of 100 to 27 by weight. To understand how much water you need for a certain amount of gypsum, multiply the weight of gypsum by 0.27. For example, 150 grams (gypsum) multiply by 0.27 = 41 grams of water. Total: for 150 grams of gypsum, 41 grams of water is needed.

Q.What are the proportions of Naturesin?

A.Mixing proportions with water (by weight): 100 (gypsum) to 27 (water).

Q.How can I colour Naturesin?

A.The material can be coloured after mixing with water, however, we recommend using powder pigments so that the colour is uniform. Classic liquid dyes for epoxy resin may not mix well in the material. Finished products can also be covered with paint (acrylic, oil, etc).

The use of large fillers is undesirable.

COD:

naturesin

Google

Google