On sale

Food Contact Transparent Epoxy Resin – 1kg

Price range: £18.85 through £139.85

Thu, 6. Nov

Ordered

Thu, 6. Nov - Fri, 7. Nov

Order Shipped

Fri, 7. Nov - Mon, 10. Nov

Estimated delivery

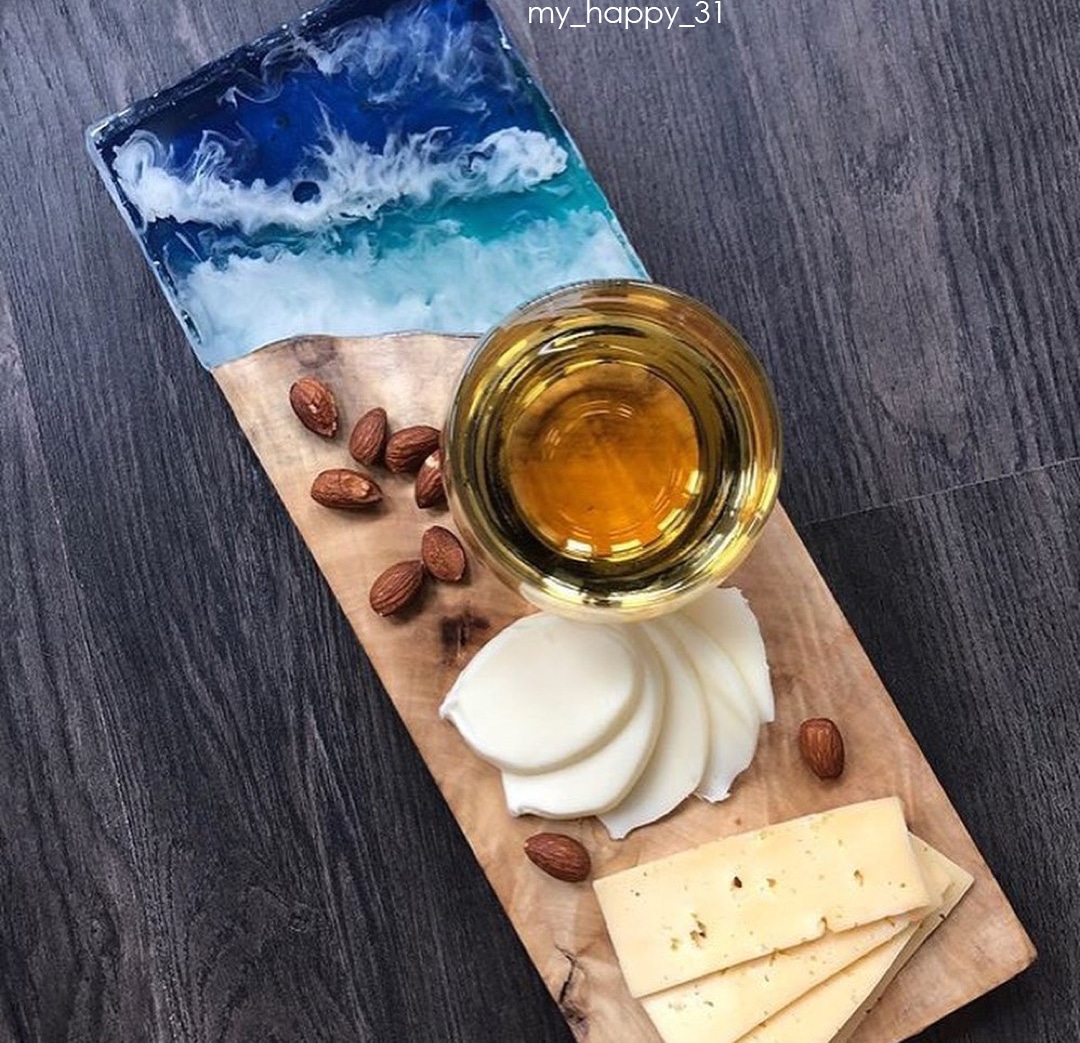

🍎EPOXYFOOD – Food contact transparent resin for your plates and cutting boards!🍎

🍎 Good for: Trays, Chopping boards, Plates, Glasses and Cutlery.

🍎 Food safe: Certified for contact with cold snacks.

🍎 Perfect transparency: A true liquid crystal.

🍎 UV filter for protection against yellowing: 10 years warranty.

🍎 Easy to use: 100:55 mixing ratio (in weight).

🍎 Heat Resistance: (Up to 70C).

🍎 Excellent mechanical resistance.

🍎 Perfect gloss finish.

🍎 Odourless.

Description

Finally, the first food contact certified* TRANSPARENT Epoxy Resin! To coat your plates and cutting boards!

Non-toxic and certified for food contact (liquids included). Two-component, high-modulus, unfilled, medium-fluidized epoxy system.

The system is composed using only raw materials included in the positive list of substances allowed for food contact (EU Regulation No. 10/2011 January 14, 2011)

Two-component unfilled high-modulus epoxy resin, medium viscosity.

Excellent surface finish and good resistance to yellowing, to be used for casting, characterized by high transparency, good outdoor stability, excellent mechanical resistance and resistance to basic and acid chemical substances.

For self-levelling casting. Its medium-high viscosity allows a wide range of applications specifically for the realization of non-toxic surfaces.

Charged with mineral aggregates of appropriate grain size, it is used to create self-levelling epoxy and screed surfaces suitable for contact with food.

The main features of this product are:

- high transparency,

- excellent mechanical resistance,

- good chemical and carbonation resistance,

- high impregnation and reinforcement of technical fabrics,

- long working time,

- glossy and self-levelling surface.

- heat resistance – up to 70 C [158 F]

💥Key features:

- ⚙️ 【RESIN FOR FOOD CONTACT】 The particular formula makes the product, once cured, perfectly compatible with any type of food and is guaranteed by a specific certification.

- 🧪 【HIGH QUALITY】 Perfectly transparent even after catalysis. Totally shiny and self-leveling, complete catalysis will take about 24/48 hours – depending on atmospheric and environmental conditions – but it will already be workable after about 10 hours.

- 🌿 【SAFE AND CERTIFIED】 All our resins are Certified Non-Toxic, Solvent-free, non-flammable, and totally safe. Certified for contact with cold snacks.

- 💧 【EASY TO USE】 The 100:55 mixing ratio makes this product very easy to use. Being a two-component resin, simply mix RESIN A + HARDENER B in the ratio indicated above the package and let it harden without the need for further additives.

- 📞 【FREE PROFESSIONAL ASSISTANCE SERVICE] Since we are directly a manufacturer, we have access to a professional laboratory that will happily help you with any complex project.

- 🇬🇧 【UK BASED TRUSTED COMPANY】 – RESIN-PRO team collect and send your order as fast as possible. We produce and realise epoxy resins since 2015. Just google our social media, where you find thousands of projects made with our products around the world.

* Documentation ensures that the raw materials used are those listed by the Ministry of Health and the migration laboratory test on cured resin samples shall furtherly ensure that the final product does not release any harmful substances, if applied following the instructions. This information can be consulted by the end users in the HCCP certification which is responsibility of the user.

Technical data

Usage ratio 100:55 (by weight)

Pot Life (150 g at 30° C) [0,33 lb at 86 F]: 40 min, therefore we recommend to design the drawing first and then apply the resin.

Film catalysis (1 mm at 30° C) [0,03” at 86 F]: 3:00′.

Full catalysis after 24 hours.

Maximum pouring level: 1.5cm*

Minimum thickness – 1.5mm

Reviews

Finally, the first food contact certified* TRANSPARENT Epoxy Resin! To coat your plates and cutting boards!

Non-toxic and certified for food contact (liquids included). Two-component, high-modulus, unfilled, medium-fluidized epoxy system.

The system is composed using only raw materials included in the positive list of substances allowed for food contact (EU Regulation No. 10/2011 January 14, 2011)

Two-component unfilled high-modulus epoxy resin, medium viscosity.

Excellent surface finish and good resistance to yellowing, to be used for casting, characterized by high transparency, good outdoor stability, excellent mechanical resistance and resistance to basic and acid chemical substances.

For self-levelling casting. Its medium-high viscosity allows a wide range of applications specifically for the realization of non-toxic surfaces.

Charged with mineral aggregates of appropriate grain size, it is used to create self-levelling epoxy and screed surfaces suitable for contact with food.

The main features of this product are:

- high transparency,

- excellent mechanical resistance,

- good chemical and carbonation resistance,

- high impregnation and reinforcement of technical fabrics,

- long working time,

- glossy and self-levelling surface.

- heat resistance – up to 70 C [158 F]

💥Key features:

- ⚙️ 【RESIN FOR FOOD CONTACT】 The particular formula makes the product, once cured, perfectly compatible with any type of food and is guaranteed by a specific certification.

- 🧪 【HIGH QUALITY】 Perfectly transparent even after catalysis. Totally shiny and self-leveling, complete catalysis will take about 24/48 hours – depending on atmospheric and environmental conditions – but it will already be workable after about 10 hours.

- 🌿 【SAFE AND CERTIFIED】 All our resins are Certified Non-Toxic, Solvent-free, non-flammable, and totally safe. Certified for contact with cold snacks.

- 💧 【EASY TO USE】 The 100:55 mixing ratio makes this product very easy to use. Being a two-component resin, simply mix RESIN A + HARDENER B in the ratio indicated above the package and let it harden without the need for further additives.

- 📞 【FREE PROFESSIONAL ASSISTANCE SERVICE] Since we are directly a manufacturer, we have access to a professional laboratory that will happily help you with any complex project.

- 🇬🇧 【UK BASED TRUSTED COMPANY】 – RESIN-PRO team collect and send your order as fast as possible. We produce and realise epoxy resins since 2015. Just google our social media, where you find thousands of projects made with our products around the world.

* Documentation ensures that the raw materials used are those listed by the Ministry of Health and the migration laboratory test on cured resin samples shall furtherly ensure that the final product does not release any harmful substances, if applied following the instructions. This information can be consulted by the end users in the HCCP certification which is responsibility of the user.

Usage ratio 100:55 (by weight)

Pot Life (150 g at 30° C) [0,33 lb at 86 F]: 40 min, therefore we recommend to design the drawing first and then apply the resin.

Film catalysis (1 mm at 30° C) [0,03” at 86 F]: 3:00′.

Full catalysis after 24 hours.

Maximum pouring level: 1.5cm*

Minimum thickness – 1.5mm

COD:

XL-Y93L-DYWFmain

Google

Google