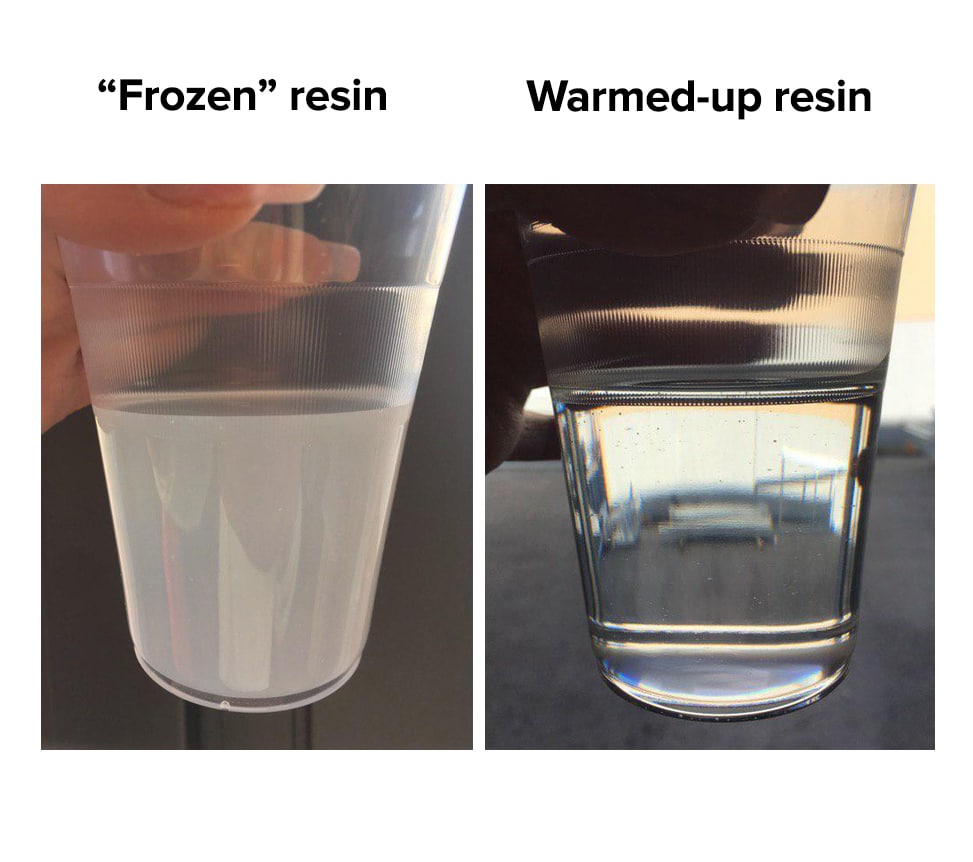

One day you may receive the parcel with epoxy resin, but after taking the goods out of the box, you may

be unpleasantly surprised that the resin has become «cloudy»: instead of the claimed crystal-clear

colour, you see a cloudy shade and/or white flakes in the sediment at the bottom of the bottle.

Explanation

Resins produced by different manufacturers differ in composition and properties, so they can also react

differently to environmental conditions. Since our epoxy resin is produced in Italy, in the Liguria region,

it is assumed that the resin will be stored in a suitable climate.

However, the United Kingdom is distinguished by lower temperatures in autumn, winter and spring,

therefore, during these seasons (and sometimes even in rainy and cool periods in summer), the resin, or

rather component “A”, can acquire a cloudy shade: from light, barely noticeable to saturated “milky”

with a dense sediment at the bottom or with dense clots in the thickness of the resin.

Can one work with cloudy resin?

Not without fixing first! Castings made from cloudy epoxy resin can have a number of defects after

curing, and your resin makes can no longer be salvaged. The most common defect is the flexibility of the

creation.

What to do?

First of all – do not panic. Cloudy epoxy in cold weather is a normal phenomenon, it is the same natural

phenomenon as freezing of water in winter in reservoirs. But as soon as spring comes, the ice begins to

melt. Almost the same thing happens with resin, albeit with some nuances: the resin “freezes” at higher

temperatures than water (at 15-20 ° C), and for its “defrosting” temperatures higher than those

recommended for its storage are needed: 50 -70 ° C.

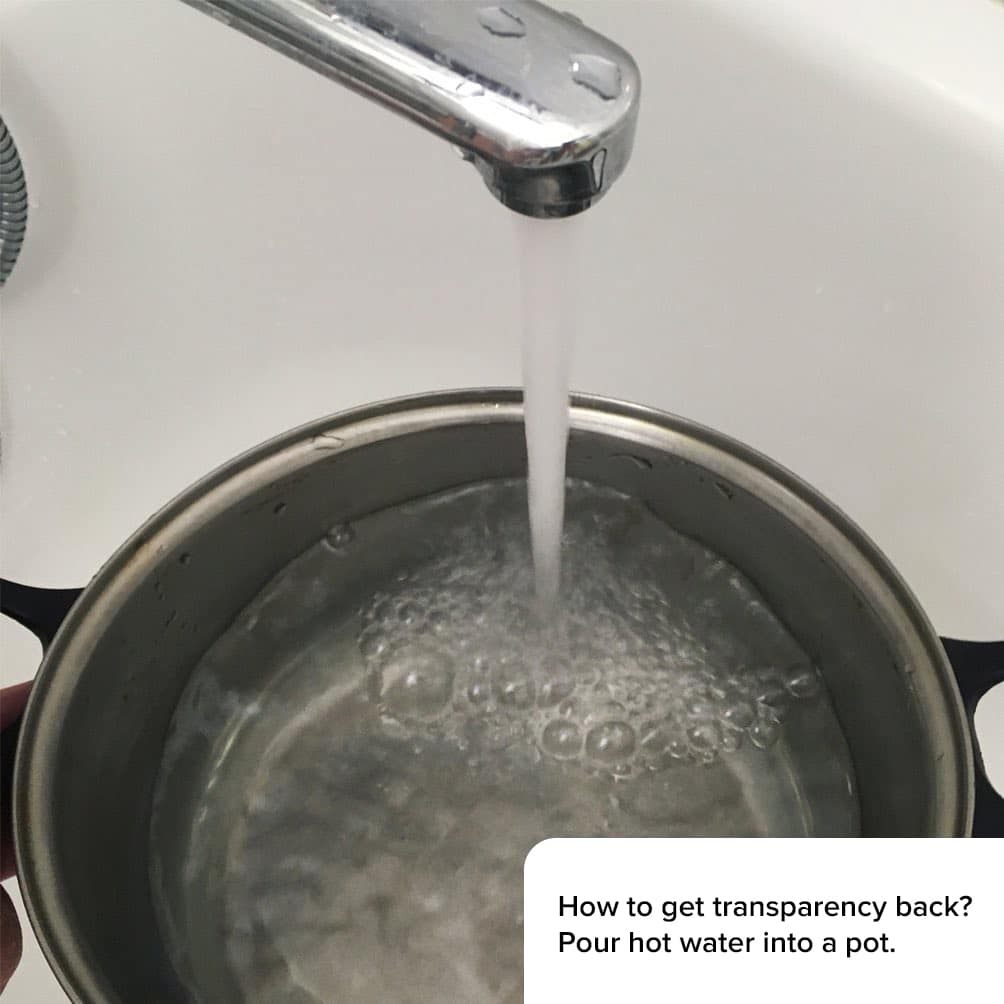

To turn the cloudy resin to its original transparency, you need to put a tightly closed bottle / canister in a

container with hot water (50-70 ° C) for 30-40 minutes until the turbidity disappears completely. This

time period is indicated for small volumes, but if you need to warm up an entire can of resin, it will take

about an hour. You can check the transparency of the resin in the cans using a flashlight. Also, in order

to eliminate the turbidity of the resin in large volumes, it will probably be necessary to change the

cooling water to hot water a couple of times.

HOWEVER: even if the resin has begun to gradually become transparent, you should not immediately

pull it out of the hot water. The resin must lie in it for some time for the “thawing” process to be

successfully completed. A perfectly clear colour is an indicator that the resin can already be used.

After such hot water procedures, the resin can be used again for its intended purpose without the risk of

getting jewelry and paintings with defects

Very nice write-up. I definitely appreciate this site. Thanks!