Epoxy resin is a versatile and durable material used for a variety of applications, from industrial to artistic. However, one common problem that arises with epoxy resin is that it can turn yellow over time, especially after it has hardened. Moreover, all classic epoxy resins are subject to yellowing, both cheap and expensive. In this article, we will explore why hardened epoxy resin turns yellow and what can be done to prevent it.

Sunlight

Exposure to UV light is one of the main reasons why hardened epoxy resin turns yellow. UV light can break down the chemical bonds in the epoxy, leading to discolouration. This is especially true for epoxy resin that is exposed to sunlight, which contains a significant amount of UV radiation.

To prevent epoxy resin from turning yellow due to UV exposure, producers must have strong UV filters in their products. This will help to protect the epoxy resin from the influence of sunlight and other sources of UV radiation.

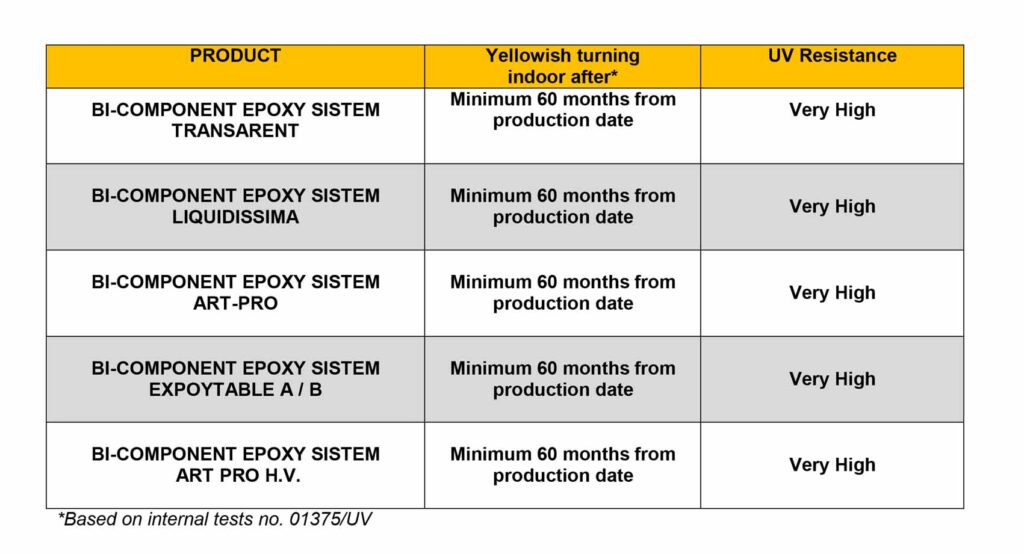

Epoxy resin by Resin Pro has a powerful protection against sunlight, therefore, if you try to store castings out of sunlight, they will not change colour after 5 or more years!

Internal tests carried out by Resin Pro experts back in 2018 showed that the first signs of yellowing of our epoxy resin appear after 60 months when stored indoors and 12 months when stored outdoors. Such a significant difference in the susceptibility of the resin to yellowing between the two types of storage lies in the fact that when stored indoors, the resin is exposed to a minimum of external factors, the main of which is direct sunlight, and storage “outdoors” means that the resin and castings from it are under constant exposure to direct sunlight, which is possible only in laboratory conditions.

You can see the results of these tests in our reports: indoor testing, outdoor testing, internal test.

And although 5 years have passed since 2018, the UV resistance of our resin has remained the same – “Made in Italy” says a lot about Resin Pro! 🙂

Relatively recently, in 2022, another yellowing test was carried out by Resin Pro team, which confirmed this quality. See results in this report: UV camera test.

-

-26% BEST SELLER

-

-23% BEST SELLER

Based on the tests, we can formulate the main rule for protecting the resin from turning yellow:

Keeping epoxy resin containers and hardened castings away from sunlight and UV radiation is the best way to protect them from yellowing.

Other reasons

Aside from UV exposure, there are other reasons why epoxy resin can turn yellow. One of these reasons is heat. High temperatures can cause the epoxy resin to break down and discolour. For this reason, it is important to avoid exposing epoxy resin to excessive heat.

You may notice that if you sometimes accidentally overheat the resin in one place with a gas heat gun, this place will turn very yellow. Be careful when removing air bubbles on the surface of the epoxy with heat sources!

Another reason why epoxy resin can turn yellow is exposure to oxygen. When epoxy resin is exposed to oxygen, it can oxidize, leading to discolouration. This is why it is important to store epoxy resin in airtight containers and to avoid exposing it to the air for extended periods of time.

Finally, the use of an improper hardener or too much hardener can also lead to yellowing of the epoxy resin. This is because the hardener can react with the epoxy in an uncontrolled way, causing it to discolour. But Resin Pro supply ready made kits which contain a resin and hardener suitable for this very resin. In no case should you use different hardeners for Resin Pro resins – everything is already ready for use and you do not need to look for an additional hardener!

Also follow the mixing ratios indicated on the resin containers by Resin Pro – they are unique to each type of resin, and failure to follow them will result in your resin simply not curing properly.

Conclusion

In conclusion, hardened epoxy resin can turn yellow for several reasons, including exposure to UV light, heat, oxygen, and the use of an improper hardener. To prevent yellowing, producers must have strong UV filters in their products, and users must take care to avoid exposing the epoxy resin to direct sunlight, excessive heat, oxygen, and other sources of discolouration. By following these guidelines, it is possible to keep epoxy resin looking clear and bright for years to come.