Epoxy resin has become a popular material for creative projects due to its versatility and ability to create beautiful and durable pieces such as paintings, stands, trays, jewelry, and other decor. However, besides applying resin to surfaces and pouring it into silicone moulds, there is another interesting way to work with it, resulting in vases and sculptures of unusual shapes. Looking at them, you might wonder, how is it possible to bend epoxy resin when it hardens into a rigid plastic state? Let’s delve into it!

Materials

First and foremost, let’s start with the materials and tools.

Choose epoxy resin suitable for flat mould castings (coasters and trays) with a sufficiently long curing time. We recommend our medium-viscosity Art Pro resin. The technique described in this article is based on the properties of this very resin.

-

-12% BEST SELLER

In addition to resin, you will need silicone moulds for coasters and trays. Keep in mind that the vases size will be significantly smaller after bending, so choose the widest mould you can find.

To create flat moulds of any shape that comes to mind, we recommend using our IGUM silicone paste for moulds: the paste itself is used to create a silicone “rim” that is applied to plexiglass, a dense film (such as a textbook cover), or our self-adhesive Shiny Shield film:

Step-by-Step Technique

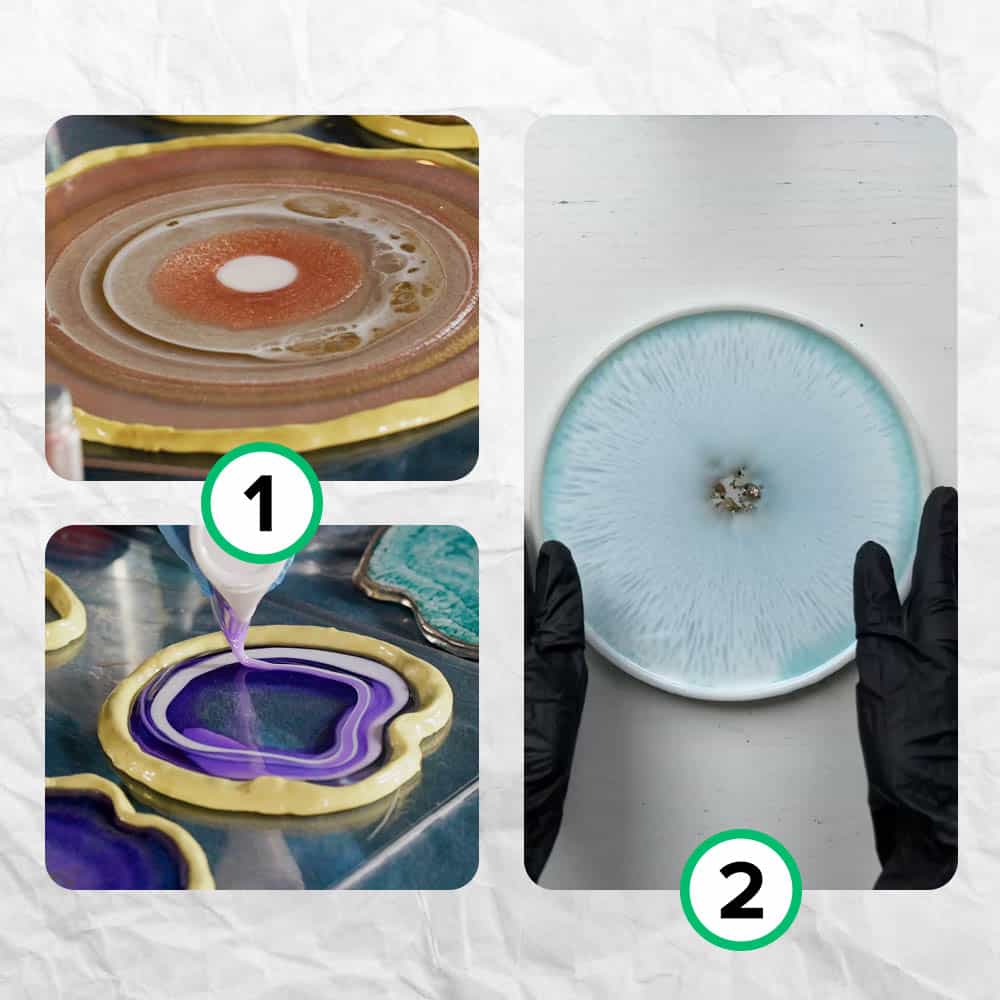

1. Mix epoxy resin, optionally coluoring it in several different colours, and pour it into a wide tray mould. To achieve a beautiful geode effect, you can alternate resin of different colours with white and transparent resin. For instance, pour a bit of white resin along the edges and in the center, then pour a bit of transparent resin in the center of mould directly on top of the white resin. Alternate colours with transparent resin until your mould is filled. Allow the resin to cure.

2. Approximately 10-12 hours after pouring, carefully check the state of the resin (through the mould, without touching the resin itself). It shouldn’t be liquid or jelly-like; it should be slightly hardened but still soft and flexible. This is the ideal moment to bend the casting. Carefully, while wearing gloves, remove the casting from the mould.

3. Take a bowl or basin (preferably metal) and gently press the casting into it to shape it. Be careful at this stage and don’t press too hard to avoid cracking the casting! Additionally, if you want uneven bends, you can take a jar with a lid or any similar object, wrap it in polyethylene film or bag, and gently “cover” the object with the casting, creating bends carefully.

4. Leave the casting in the bowl/on the jar for 24-36 hours to allow the resin to fully harden and gain strength.

Conclusion

Shaping vases and sculptures from semi-hardened epoxy resin is an engaging way to create unique decorations. But don’t forget about safety precautions; resin is harmless only after complete curing. Therefore, even when working with semi-hardened resin, wear a mask/respirator, gloves, and work in a well-ventilated area. Creativity is good for the soul, but don’t forget about your physical health ❤️

Check out our safety protection section: